By Jayesh

Food processing transforms raw ingredients into consumable foods. The food industry has undergone significant transformations leading to safer and high-quality food. Consumers want more convenience and are interested in shelf-stable health and wellness products. There is a need for efficient production to feed the growing population while ensuring food security and the expanding distribution network. This leads to the adoption of advanced food processing technologies.

High-Pressure Processing

This method uses high pressure to kill microorganisms like bacteria, viruses, and other pathogens in the food. It is used to process both liquid and high-moisture-content solid foods. It is a non-thermal technique that preserves the texture, taste, and even the nutritional values of the food. Although lethal to microorganisms, pressure treatment does not break covalent bonds and has a minimal effect on food chemistry. Moreover, the pressure ranges between 300MPa and 600MPa, it varies for different types of food items. This technique is mainly used for juices, meat, seafood, and ready-to-eat meals. The food products are sealed in flexible and water-resistant packaging and then are subjected to the high-pressure for a certain period.

Industrial Food Cutting Machines

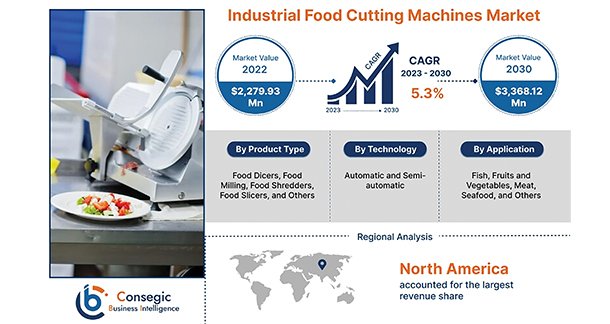

Industrial food-cutting machines are used to efficiently process large quantities of food. They are used in slicing items into appropriate shapes for large-scale food industries. They ensure consistent portioning and sizing for uniform quality. They are widely used for their hygienic and easy-to-clean operations. According to the Consegic Business Intelligence report, the Industrial Food Cutting Machines Market Market Size is estimated to reach over USD 3,368.12 Million by 2030 from a value of USD 2,279.93 Million in 2022, growing at a CAGR of 5.3% from 2023 to 2030. Food cutting machines are widely used in the food and beverage sector for slicing, chopping, grating, and more. They process large amounts of food cleanly and quickly, and are easy to clean and hygienic. The trend towards automation is driving their adoption of efficient manufacturing processes, especially for processing fruits and vegetables.

Ultrasonic Food Cutting

Ultrasonic cutting is especially appropriate for soft, frozen, or fresh food items like cheeses, meats, deli meats, pastries, etc. It is also suitable for all shapes and sizes such as plates, pieces, strips, layers, rounds, blocks, bread, and more. The ultrasonic hand-held food cutter represents a culinary instrument that utilizes ultrasonic technology to redefine precise cutting in the food industry. With its compact design and advanced capabilities, this tool transforms food preparation, providing numerous benefits and versatile applications. It uses high-frequency sound waves to cut food products, reducing waste, and improving precision. It offers benefits like clean cuts, minimal waste and maintenance, reduced friction, and heat generation. Dukane, Sonics & Materials Inc, and other major players provide ultrasonic food-cutting systems.

Microwave-Assisted Thermal Sterilization

The Microwave-assisted Thermal Sterilization (MATS) process uses pressurized hot water and long-wavelength microwave energy to sterilize food. This method takes a much shorter processing time than conventional methods. It results in less damage to sensitive nutrition and extends food product shelf life up to two years. MATS is ideal for ready-to-eat meals, baby foods, sauces, teas, juices, and more. The food is packaged and then subjected to microwave energy in a pressurized hot water environment. The microwaves penetrate the food, heating it evenly and rapidly. It offers better retention of nutrients, flavors, and textures. This technology is gaining traction in the global food industry, with major manufacturers like TATA SmartFoodz in India adopting MATS-ready packaging.

Advanced Robotics and Automation

The robotics and automation are transforming the food processing industry by increasing precision, efficiency, and safety. These are applied in various stages of food processing from sorting and packaging to cooking and quality control, that ensures consistent quality and high productivity. Robotics includes articulated robots, delta robots, SCARA robots, collaborative robots. On the other hand, automated systems involve integrating hardware and software to control machinery and processes. Automation reduces labor costs and minimizes waste, leading to overall cost savings. Moreover, modern robotic systems can be reprogrammed and reconfigured to handle different products and processes, enhancing adaptability.

Conclusion

The integration of advanced technologies drive the food processing industry towards greater efficiency, safety, and quality. As technology continues to evolve, the food processing sector will be better equipped to overcome future challenges, contribute to food security, and enhance overall consumer satisfaction.

Author Bio: Jayesh, a Professional Content Writer at Consegic Business Intelligence holds expertise in the Food and Beverages Industry.

Source: Consegic Business Intelligence: Industrial Food Cutting Machines Market