- Introduction

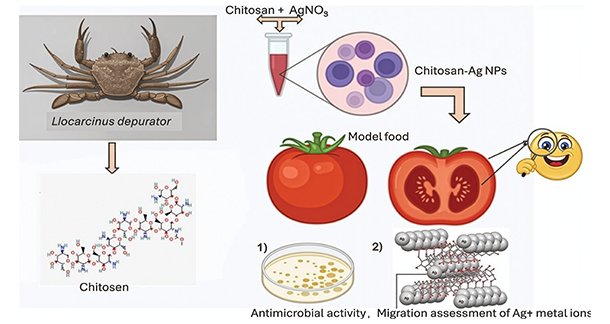

Increased need for safe, sustainable, and long-lasting food packaging is diverting attention from conventional synthetics to sustainable alternatives. Active packaging based on natural polymers with antimicrobial compounds is a promising candidate. Chitin and chitosan with silver nanoparticles (AgNPs) provide improved food preservation by antimicrobial activity, increased strength, and sustainability.

Chitin, an abundant marine polysaccharide found in crustaceans and certain fish, is a repeating unit of N-acetyl-D-glucosamine. It’s non-toxic, biodegradable, and biocompatible. Chitosan, prepared from chitin through alkaline deacetylation, dissolves in acidic solutions and is capable of forming films.Chitin and chitosan with silver nanoparticles (AgNPs) have antimicrobial activity, especially against fungi and Gram-positive bacteria. Both tend to lack sufficient strength and barrier properties, which usually must be enhanced often by combining with nanoparticles or other polymers. This is what makes chitin perfect for bioactive packaging films that prolong shelf life and maintain food safety.

- Synthesis and Chitin-Silver Nanoparticles (Chitin-AgNPs) Processing

2.1) Extraction of Chitin

Deproteinization employs sodium hydroxide (NaOH) to extract proteins from crustacean shells or fish scales; demineralization utilizes hydrochloric acid (HCl) for the removal of calcium carbonate and other minerals; and decolorization utilizes solvents such as acetone to extract pigments, leaving purified chitin for the synthesis of nanoparticles. Silver nanoparticles are prepared by in-situ or ex-situ methods:

In-situ synthesis can be achieved by directly adding silver nitrate (AgNO3) to a chitin or chitosan solution, reducing and stabilizing under controlled heat and stirring, with chitin playing both reducing and stabilizing roles.

Ex-situ synthesis involves incorporating pre-synthesized silver nanoparticles (AgNPs) into the chitin matrix and stabilizing them by interacting with functional groups such as amino and hydroxyl. Vijayaraj et al. (2023) reported a green synthesis process employing fish-scale-derived chitin for reducing AgNO3 under mild heat; a brownish color indicates successful nanoparticle formation.

2.2 Film Formation

Chitin-AgNP films are prepared by casting a uniform solution of chitin (or chitosan), silver nanoparticles (AgNPs), plasticizers (such as glycerol), and occasional bacterial cellulose nanofibers (BCNF) into molds or petri dishes. Films are air dried and condition at 50% relative humidity for a few days to stabilize them.

2.3 Structural and Morphological Analysis: Methods such as Scanning Electron Microscopy (SEM), Fourier Transform Infrared Spectroscopy (FTIR), and X-ray Diffraction (XRD) verify dispersion of AgNP in the chitin matrix and reveal chemical interactions. FTIR normally indicates peaks indicating AgNP bonding to amino groups of chitosan.

2.4 Mechanical and Thermal Properties: AgNP addition increases chitin film tensile strength, elongation, and thermal resistance. Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) indicate increased thermal stability, important for various storage and transport conditions.

2.6) Barrier Properties: Resistance to moisture and oxygen is crucial in packaging. Chitin-AgNP films exhibit a significant reduction in Water Vapor Permeability (WVP). For instance,In the study conducted by Yazdi et al. (2024) the WVP reductin with AgNPs and BCNF, significantly enhanced food preservation.

2.7) Antimicrobial Activity and Mechanism

Antimicrobial activity of chitin-AgNP films is one of their most desirable characteristics. Silver ions (Ag+) emitted from AgNPs interfere with microbial cells by:

Injuring cell membranes.

Binding to thiol groups in proteins and enzymes.

Producing reactive oxygen species (ROS).

These activities lead to the inhibition of bacteria, yeasts, and molds. The films have been reported to prevent pathogens such as E. coli, S. aureus, L. monocytogenes, and Vibrio spp. from growing.

- Food Packaging Applications

| Sl. No. | Author Name | Study Conducted | Inference |

| 1 | Yazdi et al. (2024) | Packaging of bread using chitosan film reinforced with BCNF and AgNPs | Packaging of bread using chitosan film reinforced with BCNF and AgNPs |

| 2 | Vijayaraj et al. (2023) |

Chitin-Derived Silver Nanoparticles for Enhanced Food Preservation: Synthesis, Characterization, and Antimicrobial Potential |

Coating of tomatoes and chillies with chitin-AgNP resulted in better shelf life of the product. |

| 3 |

Karolina et al.(2020) |

Biopolymers-Based Materials Containing Silver Nanoparticles as Active Packaging for Food Applications–A Review

|

Packaging of meat and seafood with chitin-AgNP films was a success. |

- Conclusion and Future Directions

Chitin-silver nanoparticle composites offer a renewable, efficient and multifunctional solution for active food packaging. The composites provide antimicrobial protection, improve mechanical and barrier function, and mitigate environmental issues related to plastic wastes.

Future lin of work:

Long-term safety experiments on nanoparticle migration.

Scalability and economical production.

Incorporation of natural antioxidants or essential oils to achieve additional functionality.

As consumers become increasingly concerned and regulatory food safety mandates become more stringent, chitin-AgNP packaging will be at the forefront of the next generation of intelligent and eco-conscious food preservation systems.

Author name: Riya Salunke, Dr Ramya V

e mail id: riyasalunke559@gmail.com

Affilated institute:Department of Food Science And Technology, Yenepoya (Deemed to be) University, Bangalore, Karnataka, India