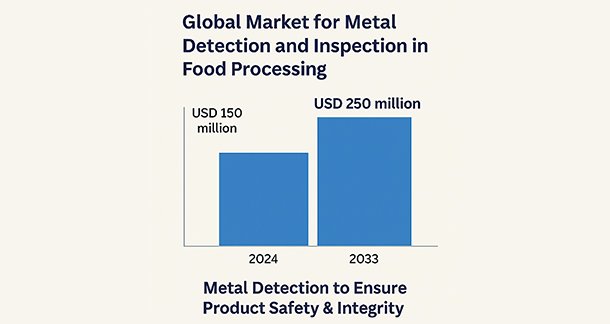

The global market for metal detection and inspection equipment in the food processing industry, valued at USD 150 million in 2024, is projected to reach USD 250 million by 2033, exhibiting a CAGR of 6.5% from 2026 to 2033. The Metal Detector for Frozen Food market is an essential segment within the broader food safety and processing industry. Metal detection is essential in the food processing industry to ensure product safety and integrity through identification and removal of contaminants.

The necessity of metal detection in the food industry stems from the increasing challenges faced by food manufacturers in upholding stringent safety standards amidst complex and often intricate production processes. Metal detection in food plays a critical role in proactively identifying contaminants, such as metal fragments, that can unintentionally find their way into products during harvesting, processing, or packaging procedures. The presence of even minuscule metal particles can trigger a cascade of negative consequences, including costly and damaging product recalls that severely impact brand reputation, potential consumer injuries ranging from choking hazards to internal harm, and significant legal liabilities coupled with regulatory fines for non-compliance with established safety standards. By implementing specialized metal detector solutions, food manufacturers can mitigate risks, safeguard consumer safety, and ensure compliance with regulatory bodies like the FDA and USDA, maintaining a strong brand reputation and adhering to food safety standards. This proactive approach helps prevent contamination and potential legal and financial consequences.

Metal is a prevalent contaminant in food production, often introduced from the machinery, handling equipment, and tools used throughout the various processing stages. Food industry metal detectors play a vital role in safeguarding the quality of unpackaged, packaged, and bulk food products by detecting and removing these metallic contaminants during processing or packaging, thus preventing them from reaching consumers. Integrating metal detection systems into a Hazard Analysis and Critical Control Points (HACCP) program is crucial for adhering to food safety standards.

Various types of metal detection systems are used in food processing, including conveyorized tunnel metal detectors, pipeline-based systems, and gravity fall systems. Metal detectors can identify ferrous and non-ferrous metals and are applicable in various food production stages, including for bread, meat, fruits, and dairy. They often include automatic reject units to remove contaminated products.

Food metal detectors are designed to identify three primary categories of metallic contaminants: ferrous metals, which are both magnetic and conductive and thus easily detectable; non-ferrous metals, which are conductive and relatively easy to detect despite not being magnetic; and stainless steel, which poses the greatest challenge due to its typically non-magnetic nature and poor electrical conductivity, especially in wet or high-salt content products. For products packaged in metal, aluminum, or aluminum foil, conventional metal detectors are typically used before packaging. However, when this isn’t feasible, specialized ‘ferrous-in-foil’ detectors are necessary to detect ferrous metals through the packaging. For non-metallic contaminants like glass, bone, ceramics, and stone, X-ray inspection systems offer superior detection capabilities.

Metal detectors operate using the transmitter-receiver method, where a metal particle passing through the electromagnetic field triggers a signal detected by receiver coils. These detectors often include automatic reject units to remove contaminated products. Food metal detectors should be strategically placed at two key points in the food production process. They must be placed at the end of the production line and in line before critical machinery.

The food manufacturing industry employs several distinct types of metal detectors, each meticulously designed and best suited for specific manufacturing environments and product types. Conveyor metal detectors are engineered for integration into high-speed production lines, where they continuously scan food products as they move along conveyor belts, making them ideal for packaged goods, baked items, and various processed foods. Gravity feed metal detectors are specifically designed for inspecting free-flowing products such as grains, powders, and nuts, and are typically installed vertically within production lines to ensure efficient and thorough detection. Pipeline metal detectors are essential for inspecting liquid, paste, and slurry products, making them indispensable for food manufacturers dealing with items like soups, sauces, or meat blends. Handheld metal detectors provide a valuable tool for spot-checking and verifying specific areas of concern or individual items within production facilities.

Partnering with external metal detection service providers offers several advantages, including higher detection accuracy, reduced downtime, and specialized expertise. These providers can detect even minute contaminants and handle complex contamination scenarios, ensuring precision and safety. Outsourcing also helps prevent costly recalls, legal liabilities, and operational disruptions, offering significant cost savings.

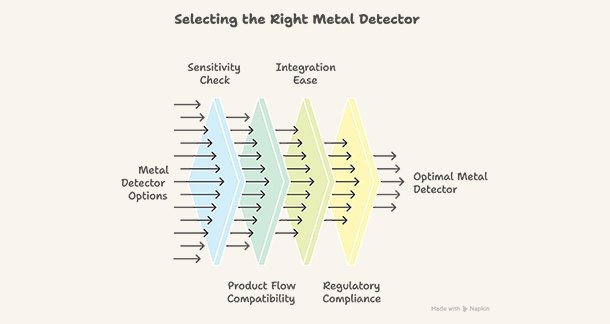

When choosing the most appropriate metal detection solution for your food processing needs, several critical factors warrant careful consideration. Sensitivity is paramount; the chosen detector must possess the capability to reliably identify the smallest metallic contaminants that pose a risk to your specific product type and consumer safety. Product Flow is another crucial aspect, ensuring that the detector is compatible with your production line’s speed and overall volume to avoid bottlenecks or inefficiencies. The Ease of Integration of the metal detection system into your existing production process is also vital for a smooth and efficient implementation. The selected detector must meet all relevant food safety standards and regulations set forth by bodies such as the FDA, USDA, and any applicable international standards.

Metal contaminants can infiltrate food products at numerous junctures throughout the intricate production process. Common sources of these contaminants include the processing equipment itself, where broken machinery parts such as blades, screws, or wires can introduce foreign metal into the food stream. Raw materials can also be a source, as metal fragments from farming tools or harvesting equipment may inadvertently remain in the initial ingredients. Furthermore, packaging materials like foil, clips, or staples used in the final product packaging can sometimes find their way into the food. Finally, human error during the processing stages, such as the mishandling or accidental dropping of tools, can also contribute to metal contamination. Recognizing and proactively addressing these potential risks through the implementation of reliable and effective food metal detection systems is absolutely critical for maintaining the highest standards of food safety and consumer trust.

About the Author:

By Venkatesh Ganapathy

(The author is a faculty member in IBS, Bangalore).