Fats and shortenings are essential components used extensively in baking and frying because they significantly influence the texture, flavor, mouthfeel, and structural properties of food products. These ingredients function not only as sources of energy but also as key technological agents that determine product quality. Their behavior during processing depends on their chemical composition and physical properties, such as melting point, plasticity, oxidative stability, and thermal resistance. Understanding these properties allows food technologists to select the right fat for a specific application and to improve product performance in both home and industrial settings.

- Chemical Nature and Properties of Fats

Fats primarily consist of triacylglycerols, in which a glycerol backbone is esterified with three fatty acids. The nature of these fatty acids whether saturated, monounsaturated, or polyunsaturated directly affects how the fat behaves during heating, mixing, and storage. For instance, fats with a higher saturation level usually have a higher melting point, making them suitable for products requiring firmness. Meanwhile, fats rich in unsaturated fatty acids may offer better mouthfeel but can be more prone to oxidation. Other important properties such as solid fat content, smoke point, and oxidative stability help determine whether a fat is ideal for frying, baking, or creaming applications.

- Types of Fats and Shortenings Used in the Food Industry

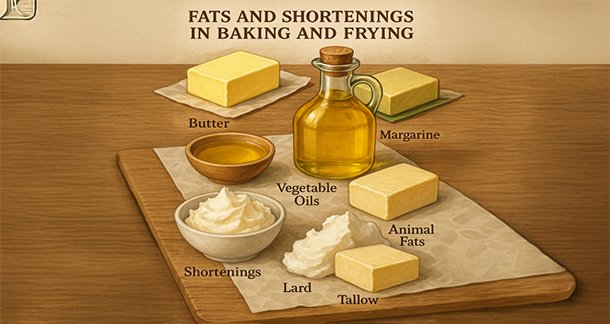

Various types of fats and shortenings are used in baking and frying, each offering unique functional benefits. Butter is widely appreciated for its characteristic flavor and its ability to aerate batters during the creaming process, although its relatively low melting point limits its use in continuous frying. Margarine, which is made from vegetable oils, is formulated to mimic butter while offering better stability and plasticity. Vegetable oils such as sunflower, soybean, canola, and groundnut oil are commonly used in frying due to their higher smoke point and neutral flavor. Shortenings, whether hydrogenated or interesterified, are specially designed to provide excellent plasticity and shortening power, making them suitable for pastries, cookies, and laminated doughs. Animal fats like lard and tallow remain traditional options valued for their flavor and stability, though their use has declined in some markets.

- Functional Roles of Fats in Baking

In baking, fats perform several critical functions that determine the final texture and structural quality of the product. One of their primary roles is tenderization, where fats coat flour particles and limit gluten formation, creating a softer, flakier texture. This is especially important in pastries, biscuits, and cookies. Fats also contribute to aeration during the creaming process, where they help trap air bubbles, increasing the volume and lightness of cakes. Another key role is moisture retention, which helps baked goods remain soft and fresh for longer periods. Additionally, the melting behavior of fats influences mouthfeel, flavor release, and the perceived moistness of the product. The type of fat used also affects spread, structure, and appearance, especially in cookies and laminated doughs.

- Functional Roles of Fats in Frying

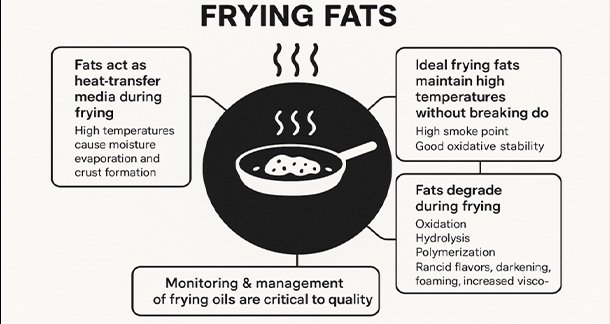

During frying, fats act primarily as heat-transfer media, allowing food to cook rapidly and evenly as high temperatures cause moisture evaporation and crust formation. The type of fat used in frying significantly affects oil uptake, surface crispness, and overall product quality. Ideal frying fats must withstand high temperatures without breaking down, meaning they should have a high smoke point and good oxidative stability. As frying progresses, fats can degrade due to oxidation, hydrolysis, and polymerization, resulting in rancid flavors, darkening, foaming, and increased viscosity. These changes compromise both the safety and quality of fried foods. Therefore, regular monitoring and proper management of frying oils are critical in maintaining product standards.

- Fat Deterioration and Stability During Frying

Frying exposes fats to heat, moisture, oxygen, and food particulates, which accelerate deterioration. Oxidation produces hydroperoxides, aldehydes, and ketones that lead to rancid flavors and unpleasant odors. Hydrolysis occurs when water from the food reacts with the fat to produce free fatty acids, which reduce the smoke point and contribute to off-flavors. Polymerization results in the formation of sticky, viscous compounds that darken the oil and reduce heat transfer efficiency. The extent of deterioration depends on the type of fat, frying temperature, and length of use. Maintaining good oil quality through controlled temperature, filtration, and timely replacement is essential for consistent frying performance.

- Modern Trends: Zero-Trans and Low-Trans Fats

With increasing awareness of the health risks associated with trans fatty acids, the food industry has shifted toward developing healthier alternatives that still deliver desirable functional properties. Modern fat modification techniques, such as interesterification, fractionation, and enzymatic modification, allow processors to produce fats with improved plasticity, melting profiles, and oxidative stability without generating harmful trans fats. High-oleic oils and specialty shortenings are now widely used in commercial baking and frying to ensure stability and performance while meeting nutritional guidelines.

Conclusion

Fats and shortenings are indispensable ingredients in baking and frying due to their ability to influence texture, mouthfeel, structure, and flavor. Their chemical composition and physical characteristics determine how they behave during heating, mixing, and storage. By understanding the functional roles and stability requirements of different fats, food technologists and bakers can make informed choices that optimize product quality, enhance consumer satisfaction, and ensure safe food production. As industry trends move toward healthier and more stable fat systems, the application of modified and zero-trans fats continues to expand, offering improved solutions for both baking and frying.

References

Bansal, G., Zhou, W., Tan, T. C., Neo, F. L., & Lo, H. L. (2010). Lipid oxidation in frying oils and fried food.Food Chemistry, 122(3), 621–627.

Berger, K. G., & Hamilton, R. J. (1995). Frying oils. In R. J. Hamilton & R. Hamilton (Eds.), Deep frying: Chemistry, nutrition, and practical applications (pp. 33–54). Springer.

Choe, E., & Min, D. B. (2007). Chemistry of deep‐fat frying oils.Journal of Food Science, 72(5), R77–R86.

Ghotra, B. S., Dyal, S. D., &Narine, S. S. (2002). Lipid shortenings: A review. Food Research International, 35(10), 1015–1048.

Gunstone, F. D. (2011). Vegetable oils in food technology: Composition, properties and uses (2nd ed.). Wiley-Blackwell.

Kamel, B. S., &Deman, J. M. (Eds.). (1990). Fats in food products.Springer.

Kruschitz, H. (2015). Fats and oils in bakery products. In S. Clark, T. Jung, & B. Lamsal (Eds.), Food processing: Principles and applications (2nd ed., pp. 367–383). Wiley-Blackwell.

Maskan, M. (2003). Change in colour and rheological behaviour of sunflower seed oil during frying and after adsorbent treatment of used oil. European Food Research and Technology, 218(1), 20–25.

Rios, R. V., Pessanha, M. D. F., Almeida, P. F., Viana, C. L., &Lannes, S. C. (2014).Application of fats in some food products.Food Science and Technology (Campinas), 34(3), 675–686.

Rossi, M., Alamprese, C., &Ratti, S. (2019). New trends in fat technology for bakery products.Current Opinion in Food Science, 27, 10–15.

Saberi, A. H., & Huang, Q. (2016).Interesterified fats and oils in food applications.Annual Review of Food Science and Technology, 7, 139–165.

About Author

Dr. Asha Kumari

Dr. Ruchi Verma

Department of Food Processing and Technology

Gautam Buddha University, Greater Noida-201312

Corresponding author mail id: ruchiverma0715@gmail.com