Plant manufacturer Devex supports companies in the food industry from the product idea to the customized drying plant

“Since Corona, end consumers have been buying food differently,” says Christoph Markmann, managing director at plant manufacturer Devex. “On the one hand, food should have a long shelf life, but on the other hand, it should also be healthy and taste good.” This is where Devex comes in with its drying systems for the gentle drying of food, in which natural color, taste, and all nutrients are retained.

“Since the pandemic, the shelf life of food has played a role in preparing for shortages if necessary. And just as important: since then, there has been a new awareness of healthy eating.” And Markmann should know, because his company Devex builds drying systems for the food industry. “Since 2020, demand has noticeably increased; we have installed massive new capacities for our customers worldwide to dry every conceivable type of food.” This makes sense, as nutritional trends toward enjoyment, health, and longevity are rapidly spreading via social media. “What used to take 20 years to go from the upper crust to the common citizen is now passed on in less than a year,” Markmann satirizes.

Highly functional foods as tasty snacks

A glance at supermarket and drugstore shelves shows that while the selection of dried fruit was still quite limited before the pandemic, today you can find everything from local apples to exotic mangoes and everything in between. End consumers eat dried fruit as an addition to healthy muesli, for example, but also simply as a snack between meals. “The development in the drying of fruit and vegetables has not only preserved all the nutrients, but also has an aesthetic component,” says Devex’s MD Markmann.

“In the past, all dried fruits looked like raisins. Thanks to our gentle drying concepts, however, our systems preserve the shape and color of the original product. We only remove the water from the raw materials. This makes the products look almost as good as fresh.” The gentle drying processes used in Devex systems preserve almost all vitamins, antioxidants, and especially the polyphenols in the product. “Dried fruit provides a real explosion of flavor for consumers, as it is concentrated by the removal of water, but still fresh and fruity,” says Christoph Markmann.

„Unlimited shelf life“ – drying at room temperature

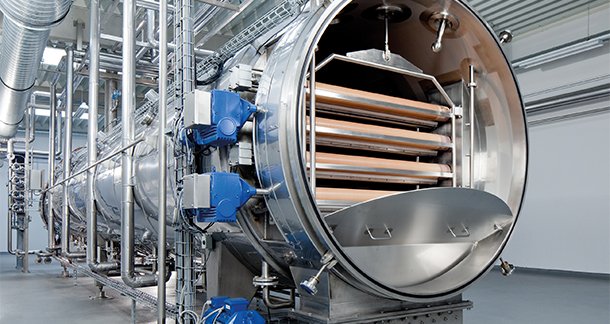

Devex dries food using vacuum dryers and freeze dryers. Vacuum drying is a process used to manufacture ready to eat products such as instant soups or instant drinks – from classic peach iced tea to trendy matcha lattes. But Devex can also dry a wide variety of fruits and vegetables using vacuum drying to increase their shelf life. “‘Highest shelf life’ is a slogan we always like to give our customers,” says Markmann. “It is always very well received in all areas of the food industry.” The drying process works as follows: The product is placed under vacuum in the chamber of the drying system. Due to the reduced air pressure (10–20 mbar), the vapor pressure within the water in the product, becomes greater than the pressure in the chamber. This causes it to evaporate – even below room temperature. As a result, the valuable constituents are not destroyed, as is the case with conventional spray dryers.

Gold standard freeze drying: hardly distinguishable from freshly harvested fruit

Freeze drying is a special type of vacuum drying and is even gentler than pure vacuum drying. Markmann explains the advantage as follows: “The very careful pre-freezing of the product causes tiny ice crystals to form. These ensure that the cell structure and color are completely preserved after drying. As a result, the product is visually almost indistinguishable from its freshly harvested counterparts after drying.” In the drying chamber, which is evacuated to around 1 mbar, the water in the raw material changes its state at around minus 20 degrees Celsius through sublimation, the transition of water from ice to gas. The water vapor is extracted from the chamber. What remains is visually appealing dried material.

“Freeze drying is the gold standard for preserving important properties of a product. Our customers want to preserve the nutritional properties of their fruit, vegetables, or other raw materials at reasonable costs. Because that’s what the end consumer appreciates when buying a high-valued product,” says drying expert Markmann. “In addition, fruit juice concentrates from the freeze dryer can be perfectly reconstituted. This is particularly important for beverages so that consumption by the end consumer is as easy as simply adding water.

Exotic applications possible in addition to foodstuffs

Devex drying systems are also used in exotic applications. “We are currently working on using the slightly less-expensive vacuum drying process to dry plant components from which our customer wants to produce a sustainable adhesive that is virtually chemical-free,” reveals Markmann.

About DEVEX

DEVEX Verfahrenstechnik GmbH is a global provider of process engineering solutions with a focus on extraction, evaporation, and drying. The company’s areas of expertise are already reflected in its name: Drying – Evaporation – Extraction – DEVEX. DEVEX services and DEVEX systems are used in a wide variety of industries and companies, particularly in the food and pharmaceutical industries. For many years, DEVEX has been supporting its customers with tailor-made solutions for all requirements relating to thermal process engineering.

For further information: www.devex-gmbh.de