Possibilities, opportunities and experiences at WDS with the use of artificial intelligence in confectionery machines

When we think of artificial intelligence, we initially imagine a futuristic, digital world. AI is already being used in numerous industries and areas of life and reputedly opens up almost unlimited possibilities. In order to make meaningful use of AI, a realistic picture of its possibilities and limits is extremely important.

Winkler und Dünnebier Süßwarenmaschinen GmbH (WDS) is one of the world’s leading manufacturers of machines for the confectionery industry for all pourable and tearable masses. The machine portfolio starts with independent depositing machines and laboratory depositors and progresses through small, fully automatic production machines to highly flexible large-scale plants for chocolate, gum and jelly, toffee and fondant or hard candy.

Field report on digitisation at WDS

A few years ago, WDS started to look for modern solutions for the confectionery industry with its own digitisation department. This resulted initially in lots of ideas and first tests with easily accessible tools such as ChatGPT or Microsoft Copilot. These were a good starting point to get a feel for what is possible and what limits currently still exist.

When talking about artificial intelligence, many people think of ChatGPT first. However, Large Language models like ChatGPT are only one very general model family among thousands of other AI models. So when AI is mentioned in this text, it does not necessarily mean a GPT model. Yet specialised tools and expertise are necessary to work with AI technology.

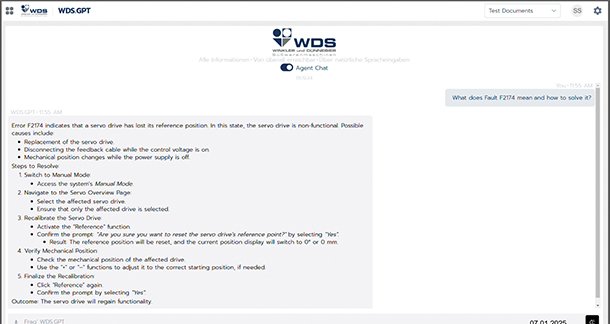

Working together with the Fraunhofer Institute, a theoretical basis and in-company know-how was built up at WDS to begin with. The initial focus of development was on the internal development of WDS.gpt – a tool that interacts with the WDS knowledge database and provides immediate answers to all questions during operation. This first project got off to a very positive start and provided very gratifying results. Motivated by this success, the idea was developed not only to tap into existing knowledge databases, but also to intelligently analyse further sources of knowledge such as assembly reports and feed the contents in a structured way to the WDS.gpt. This way, thousands of error and solution possibilities were transformed into a structured database, and the capability of WDS to achieve effective error correction and the transfer of know-how across different projects and over a long period was significantly increased.

The WDS.gpt for internal use makes it possible to ask questions on almost any topic in natural language, making it very easy to operate. The system determines the information available in the saved database and puts it together clearly in a very short time. In addition, the sources of information are indicated, so that the answers can be checked and reproduced.

In the next step, the knowledge gained shall not only be able to be used internally by WDS but also by their customers. The existing SweetConnect platform provides an ideal basis for this. Research is currently being done on the possibilities of providing knowledge specifically, meaningfully and securely.

AI in the confectionery production plant

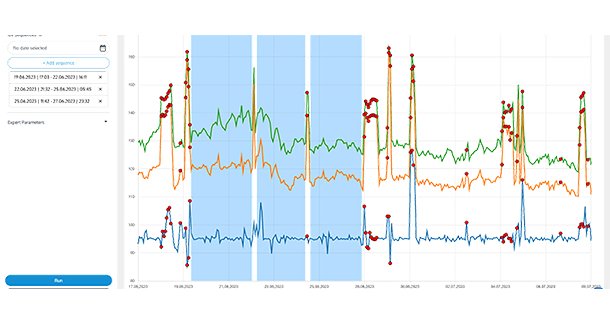

A confectionery machine produces a large amount of data. Using a smart measuring mould such as e.g. SmartMould, it is already possible to continually record process data in the mould flow and to evaluate this using statistics methods or simple limit value analyses. However, it is still not currently possible to make efficient use of the complete data – which is where the greatest opportunities offered by AI applications come into the picture.

The immense quantity of data from the production plant can be processed almost in real time by artificial intelligence and can also be evaluated linked with historic data in order to guarantee automated and continual process monitoring. Error patterns or anomalies can be recognised in good time and can often be optimised before they lead to a real problem.

An AI application is thus designed to support trained personnel in making fast and goal-oriented decisions. What it is not designed to do is make the use of autonomous machines without operating personnel possible.

Limits in the use of artificial intelligence

Alongside the many conceivable possibilities, some data is less suitable for the use of AI. The observation of rules and regulations when handling sensitive data can make the use of AI more difficult. In addition, AI does not have moral reasoning, which means that when moral decisions have to be made, human judgement must always be preferred over the AI decision. Ecological aspects also have to be taken into account, since AI solutions require a lot of resources. If the expected ROI is low, traditional or hybrid approaches can offer a more suitable cost-benefit ratio. For uses subject to high safety requirements, such as in medical technology or aviation, a wrong decision can have far-reaching consequences. Risks should always be considered carefully in such cases.

Examples of shop floor solutions with artificial intelligence

An assistance chat like WDS.gpt can search for contents in many documents and sources at the same time and clearly summarise only the most important information. The compiled information must be able to be traced back to its source at all times, so that information can be verified. In future, this work would be done by a depositing assistant, which can answer questions such as “Why is the product weight not OK?”, “What order number does drive xy have?” or “How do I change the pump system?”.

Equally, report functions would be easier to implement: AI-based assistants reliably carry out tasks such as “Prepare a daily report on OEE and plant errors” or “Send an e-mail report if you recognise a deviation in comparison to the last 30 days”.

One of the greatest talents of a language-based AI is understanding and creating source code. We can make use of this talent when creating dashboards. We just have to explain to the AI in natural language what we would like to see and where the data is to be taken from. The AI can then create a clear Grafana dashboard with the necessary data.

Further information: www.w-u-d.com.

About the author:

Daniel Bötz is Team leader Digital Services at Winkler und Dünnebier Süßwarenmaschinen GmbH.