In recent years, dairy farms have undergone significant changes, with technology playing a pivotal role in transforming the way farmers work. One of the most important developments has been the use of robots. These machines are now handling many tasks that were previously done only by people, such as harvesting cows, feeding them, cleaning establishments and even monitoring the health of animals. As labour shortages and increased production demands continue to challenge farmers, robots are intervening to provide relief from these demands, offering continuous, efficient, and reliable support throughout the dairy industry.

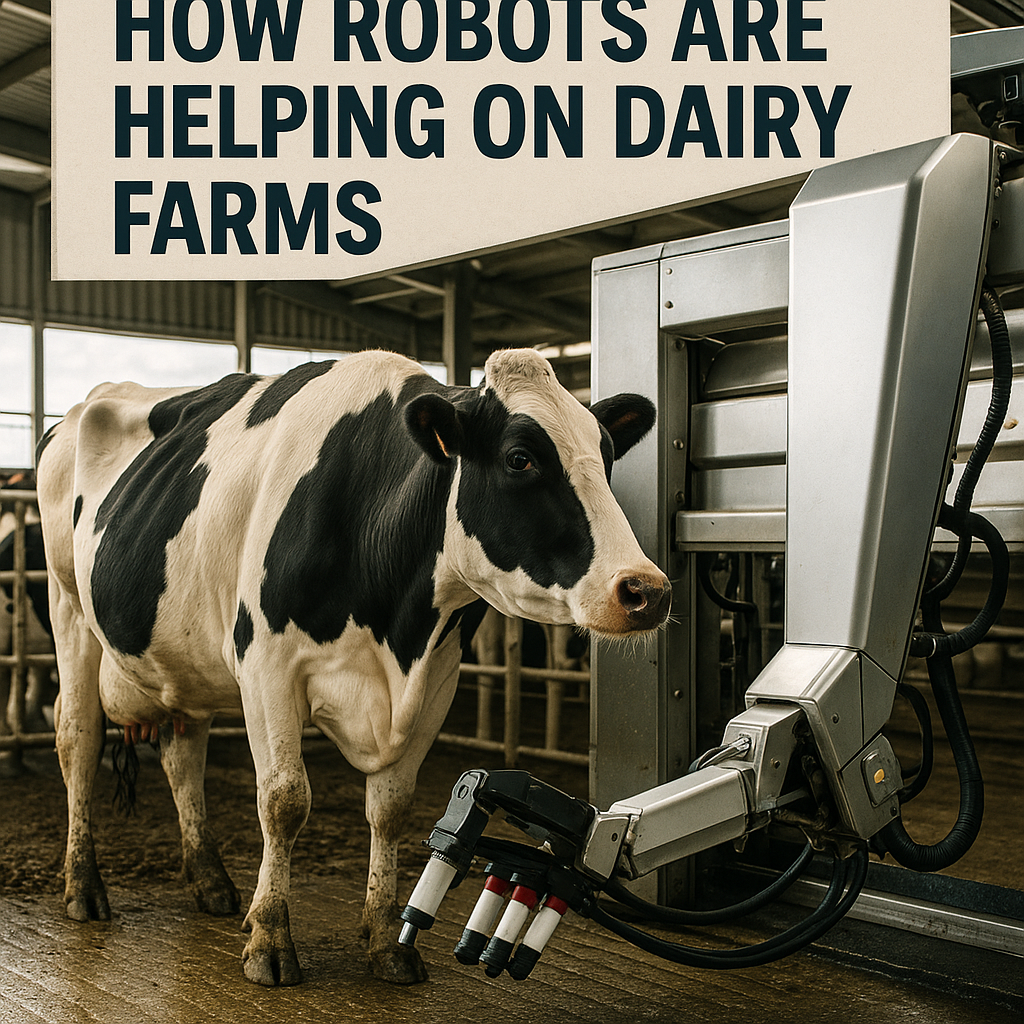

One of the most common uses of robots in dairy farms is in cropping. The automated milking system, also known as a robot milking machine, allows cows to give milk without human hands. Cows can enter the stables whenever they want, which often makes them more comfortable and less stressful. The robot uses sensors or cameras to detect teats, clean them and attaches milking cups. Milk is collected and sent directly to storage tanks, while essential data on the cow, as well as the quantity and quality of milk, are recorded. After harvesting, the machine automatically removes the cup, rewards the cow with food and cleans itself before the next cow arrives. This system not only saves time for the farmer but also significantly improves the health and comfort of the cows, demonstrating a profound commitment to animal care. Farmers also receive detailed information about each cow, which enables them to make more informed decisions regarding herd management. Many farms that adopt robotic harvesting systems report an increase in milk production and an improvement in the overall well-being of their animals.

Feeding cows is another task that requires a significant amount of time and is now often managed by robots. The robot feeding system can prepare and deliver food to the cows several times a day. These machines ensure that the right amount and type of feed is delivered to each group of animals, whether it is young cattle, pregnant cows, or high-producing milkers. By providing fresh and consistent food, the robots encourage the cows to eat more and waste less. This not only improves the nutrition and milk production of cows but also reduces the cost of food. In the past, farmers often had to hand-mix and distribute food using large tractors. With food robots, the process becomes significantly more efficient, enabling farmers to concentrate on other essential tasks.

Another area where robots are making a big difference is the cleaning of installations. Clean establishments are essential for the health and safety of cows. Dirty places can cause infections, poor health and unpleasant living conditions. The robotic barn cleaners, also known as manure scrapers, visit this establishment several times a day to remove waste. These slow-moving machines silently clean the floor, keeping the environment cleaner than traditional manual cleaning, which is done only once a day. Cleaner barn means that the cows are happier and healthier and fewer vet visits. These robots also help reduce the amount of time that farm workers dedicate to physically demanding cleaning tasks, making the farm a better place for both animals and people.

Robots also play an essential role in monitoring the health of cows. Many farms now use intelligent sensors, collars, or ear tags to track individual animals. These devices can record the number of steps the cow takes, the distance she travels, her body temperature, and her location within the station. Some systems also monitor guardians of mastication or alert farmers when a cow is in a silo or showing signs of disease. This type of real-time monitoring allows farmers to identify problems early, treat sick animals more quickly, and make informed breeding decisions. In the past, farmers had to rely on experience and observation, which could cause early warning signs to disappear. With robotic monitoring systems, farms can prevent problems rather than react to them once they occur.

Even young animals, such as cattle, benefit from the use of robotic technology. Food robots for cattle help to ensure that the youngest members of the herd receive adequate nutrition. These machines automatically mix and deliver milk or replacement milk to each dog according to their needs. A label identifies each third, and the robot tracks how much and with what frequency it comes. It creates a consistent feeding routine, which supports healthy growth and reduces stress for both the animal and the farmer. Healthy cattle are more likely to become strong and productive cows, so it’s essential to invest in their care early on for the long-term success of the farm.

There are many benefits of using robots in dairy farms. This saves time and reduces the need for manual work, which is especially important since there are fewer and fewer people willing to work in the fields. Robots help make farms more efficient, consistent, and scalable. They also contribute to better care for animals by allowing cows to follow their natural routines, as well as choose when to eat or be ordered. It reduces stress and generally improves overall health. In addition, robots collect large amounts of data that help farmers track yields and the health of their animals, enabling them to detect problems promptly and make informed decisions.

However, several challenges are associated with the use of robots in dairy farms. The most significant of these is the initial cost. Robot systems can be costly to purchase and install. For example, a robot machine can cost more than $150,000, excluding installation and training costs. However, it’s essential to note that while robots can perform many tasks, they still require farmers to understand how to operate and maintain them effectively. Farmers play a crucial role in ensuring that the robots are functioning correctly and that any issues are promptly addressed. If something goes wrong, it can disrupt the entire farm’s operation. In some rural areas, poor quality of internet or electricity can also hinder the use of advanced robotic systems. Despite these obstacles, many farmers believe that robots are a worthwhile investment and are key to competitiveness in the modern dairy industry.

Despite these challenges, the use of robots in dairy agriculture continues to grow. Increasingly, farms in countries such as the Netherlands, Germany, Canada, and the United States are adopting robotic technologies. Even the smallest farms have begun using robots to enhance efficiency and reduce labour demand. Experts estimate that in the next decade, nearly half of all dairy farms could use robots. As technology advances, we can expect to see robots become increasingly mobile, intelligent, and user-friendly. These advances could include advancements in artificial intelligence, energy-efficient design, and improved systems for analysing data and managing swarms. The future of robotic technology in dairy farming is promising, with potential advancements that could further revolutionise the industry.

A real example of robotic success can be seen in a familiar farm that has recently adopted automation. The Patel family, which runs a farm with 80 cows, used to harvest their herds by hand twice a day, feed them tractors and clean the stalls by hand. These tasks occupied most of their day and required a large number of workers. After installing a robot feed system, a robot feeder, a cleaner robot and health sensors for the cows, their routine changed completely. Cows now choose when to harvest, feed several times a day and live in a clean and low-stress environment. Patel now spends more time managing his business, taking care of the animals and enjoying family life while producing more milk with less stress and effort.

Ultimately, robots are enabling dairy farmers worldwide to work more efficiently, enhance animal care, and boost production. These machines are not replacing farmers; they are working with them to make farms more sustainable, comfortable and productive. With continued innovation, robots will likely play an even more critical role in the future of dairy agriculture. As more farms adopt this technology, the industry can look forward to higher-quality milk, happier cows, and a better life for farmers and their families.