By Anurag Mishra

Traceability of any product is nothing but ability to track every aspect of manufacturing and distributing a product. In case of food and beverage, it becomes critical to trace the product from “Grass to Glass” or “farm to fork” . Traceability is extremely important in case of any crisis like withdrawal, recall, and identifying the root cause of any issues raised by customer / consumer / regulatory bodies . In India, FSSAI mandates an end to end traceability of all food products .

There are 2 types of traceability, Forward and Backward. Forward traceability is ability to trace the forward movement of that product (after manufacturing) in supply chain, mainly in warehousing, transportation, and further distribution till retailors . Backward traceability is tracing the backward manufacturing/ processing aspect like all steps of processing, used raw materials , packaging materials , process aids etc.

In dairy industry , farm level traceability will fall under backward traceability. Farm level traceability is noting but tracing the milk till the first level of its collection. These days, it is extremely important because if any chemical contaminants like aflatoxin , melamine or inhibitory substances like antibiotics or adulterants , are identified in any batch of milk then farm level traceability becomes the most important factor to identify the district/block/village/farm , from where the contamination has happened .

For example if one dairy organization is collecting milk from 10000 farmers and after that day’s collection if some adulterant / contamination is observed then dairy must be able to identify that from which farm adulterated or contaminated milk was supplied.

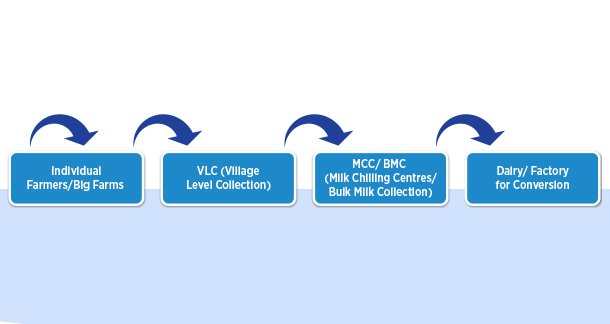

Generally supply chain of milk in India from the farmer till consumer is :

So following the above mentioned flow, farm level traceability is tracing milk from Factory to BMC/MCC to VLC to Individual farmer.

In the Indian context , most of the dairy organizations are not able to trace back till farm/ farmer level and challenges lies in each step of the supply chain like :

Challenges at Factory Level: Being an essential part of daily meals, milk is processed continuously by most of the dairy organizations. However value added products ( Ghee , paneer , flavoured milk etc) may take a break but SKUs like pouch milk, curd etc. are produced continuously with only interval of CIP (Cleaning in Place ) . Additionally, same lines, tanks, and fillers are used to produce many flavors / types of SKUs so if not maintained/ recorded/ monitored properly, then factory can be the biggest misleading chain while doing traceability.

For example, if one factory is producing full cream milk and after completion of that plan, toned milk is produced. If tank numbers and other required details are not changed in the production log, then while doing traceability you will never get the correct results. This is because wrong tank number will lead to the wrong details of collection from BMC and so on.

Also factory must keep the retention sample ( @ Controlled Temperature ) of each tankers received from BMCs/ MCCs so in case of any issues, by analyzing the retention sample of all the BMCs/ MCCs , it can be traced that from which BMC contaminated sample was received.

This only includes Farm level traceability as overall traceability will include other verticals as well like ingredients, process aids, packing material etc.

Challenges at BMC / MCC Level: Once the issue is observed that XX tanker has collected milk from BMC “A”, then BMC must be capable of identifying the VLC from where said milk is collected. However, as per current practice, BMC checks only basic parameters like fat, SNF, and basic adulterants only. So, in case of any contaminations like Antibiotics / Melamine and Aflatoxin , it will be impossible to get the culprit VLC from where that milk is supplied . To do that, all the BMCs must keep retention samples of all the VLCs. In India this is the biggest challenge as most of the BMCs are not retaining the samples of VLCs. Hence, further traceability is not possible.

The reason of not keeping the retention samples are unskilled manpower , lack of infrastructure like refrigeration for maintaining required temperature of samples and less awareness from the dairies . So, if we need to trace up to VLCs, then we must maintain the retention samples of each VLC . Doing this is not difficult, as small awareness and one time investment on Infra will mitigate this issue.

Challenges at VLC Level: As mentioned earlier retention samples are extremely important to trace to the farm level. However, it is really complex in the Indian context because at VLCs approx 50-100 farmers supply the milk and maintaining retention samples at VLC level will be a tough task. This is because the VLC is nothing but a small room and VLC in charge shut the VLC after collecting and handing over the Milk to BMC in charge who carries the cans in a small vehicle. Additionally, some farmers may sell only a liter of milk so maintaining a retention sample of 1 liter of milk is impossible .

In a nut shell , maintaining retention samples at VLC is a big challenge and will require significant cost and resource requirements like dedicated VLC in charge , Fridge, and other infrastruture related requirements .

So, given the current scenario, it will be great if we can maintain the traceability up to VLC level i.e. from which VLC the milk is supplied and then next day, the technical team can visit that VLC to check the milk from each farmer. This will enable to mitigate the ongoing issue and prevention can be done for future. If we need to track the issue which has happened , then Indian infrastructure is not capable of this requirement and we need to invest significantly to make this up to individual farm level .

The question to ask in this senario is how countries like New Zealand, European countries etc. are able to trace up to farm level . The simple answer is “Farm Size and use of technology “. This is because in developed countries, typical farm size varies from 200- 5000 cows/ buffalos and a day’s collection from 1 farm is much higher than total VLCs collection. Their farms supply milk directly to factory. So it is essential to understand that keeping larger farms’ retention sample at factory is much simpler than Indian practices of VLC to BMC to factory .

Additionally, with the help of technology, most of the contaminants / adulterants are checked very quickly and in a cost effective way .

Now a days, given the focus of Indian regulatory bodies and general food safety awareness among the people of India , many dairy start ups are now promising animal level traceability . The quantum may be very small but the changes are happening and we can expect the same from big dairy organizations .

Anurag Mishra (Food Safety Professional and can be contacted @ Anurag.ft@gmail.com)