With the present day society nowadays considering food safety troubles very lots, there may be the very crucial component of technological advancement that has been critical in preventing hazard and protective customers. One of such innovative equipment and at the leading edge of these efforts is predictive analytics. By utilising the ample records, statistical methods, and synthetic intelligence, analytical predicting is changing the manner the food sector anticipates and avoids the risks of food protection as one of the risks. This paper examines the function of predictive analytics to enhance food protection practices with a particular recognition at the impact, technique, and the restrictions it seeks to deal with.

The Power of Data in Food Safety:

Foodborne ailments and contamination incidents will have severe results for public fitness and logo reputation. Traditional strategies to food safety control rely on reactive measures, together with identifying and addressing issues once they arise. Predictive analytics, however, takes a proactive stance through the use of ancient and real-time records to forecast potential risks and save you them from going on.

Understanding Predictive Analytics in Food Safety

Predictive analytics includes the use of ancient records, statistical algorithms, and machine gaining knowledge of techniques to become aware of the chance of future effects. In the context of food safety, it method leveraging giant amounts of information from numerous resources to forecast potential protection risks and take preventive movements

Key Components of Predictive Analytics in Food Safety:

- Data Collection: Gathering information from multiple sources, including:

- Supply chain data (e.g., sourcing information, transportation logs)

- Environmental monitoring systems (e.g., temperature, humidity sensors)

- Quality control records (e.g., test results, inspection reports)

- Consumer feedback (e.g., complaints, social media mentions)

- Regulatory compliance reports

- External data sources (e.g., weather patterns, economic indicators)

- Pattern Recognition: Identifying trends and patterns that may indicate potential safety risks. This could include:

- Seasonal variations in food safety incidents

- Correlations between environmental factors and contamination rates

- Emerging trends in consumer complaints

- Risk Forecasting: Predicting the likelihood and potential impact of food safety incidents. This involves:

- Developing probabilistic models

- Scenario evaluation

- Impact evaluation

- Actionable Insights: Providing recommendations for preventive measures and interventions, such as:

- Modification of process parameters

- Changes in vendor selection

- Enhancement of testing systems

Applications of Predictive Analytics in Food Safety

- Supply Chain Risk Management

Predictive analytics can help identify potential risks at various points in the supply chain:

- Supplier Risk Assessment: By studying historical overall performance data, predictive fashions can determine the reliability of suppliers. For instance, a version may do not forget elements consisting of past delivery timeliness, great consistency, and compliance with safety requirements to generate a danger rating for every dealer.

- Environmental Impact Forecasting: Predictive analytics can assume how environmental factors may affect raw material first-rate. For instance, weather data will be used to are expecting crop yields and first-rate, permitting food producers to regulate their sourcing techniques proactively.

- Transportation Optimization: Analytics can optimize transportation routes and conditions to limit the risk of spoilage. This would possibly contain thinking about elements consisting of temperature fluctuations, transit instances, and historic overall performance facts of different transport methods.

- Microbial Growth Prediction

Predictive analytics can forecast the likelihood of microbial growth in food products by analyzing factors such as temperature, humidity, pH levels, and product composition:

- Shelf Life Optimization: By modelling the boom fees of particular microorganisms under numerous situations, predictive analytics can help determine choicest storage situations and more as it should be expect shelf life. This can reduce waste and minimize the danger of promoting spoiled merchandise.

- High-Risk Batch Identification: Analytics can flag batches that are at better chance of contamination based on production conditions, element assets, or other elements. This lets in for greater targeted and efficient checking out protocols.

- Process Parameter Optimization: By studying ancient records on microbial boom on the subject of various processing parameters, predictive models can endorse gold standard settings to reduce infection risks while keeping product quality.

- Early Warning Systems

Predictive analytics can serve as an early warning system for potential food safety issues:

- Consumer Complaint Analysis: By applying herbal language processing and sentiment analysis to customer court cases, predictive models can discover emerging styles that would imply a food safety problem before it turns into widespread.

- Social Media Monitoring: Analytics equipment can experiment social media platforms and news sources for early signs of foodborne infection outbreaks. By detecting uncommon spikes in food-associated lawsuits or discussions, these systems can alert food safety teams to capability issues in near real-time.

- IoT Sensor Integration: The Internet of Things (IoT) lets in for the gathering of big amounts of real-time records at some stage in the food deliver chain. Predictive analytics can system this information to come across anomalies that would suggest safety dangers, along with temperature fluctuations for the duration of transportation or uncommon patterns in production line sensors.

- Regulatory Compliance

Predictive models can help food businesses stay ahead of regulatory requirements:

- Compliance Forecasting: By studying historical regulatory statistics and industry developments, predictive fashions can count on destiny regulatory adjustments. This permits businesses to proactively adjust their techniques and keep away from non-compliance issues.

- Risk-Based Inspection: Regulatory our bodies are increasingly more the use of predictive analytics to prioritize inspections based totally on hazard elements. Food groups can use comparable models internally to perceive areas of capability non-compliance before they end up issues all through professional inspections.

- Resource Optimization: Predictive analytics can assist businesses allocate sources extra correctly for compliance-related sports. By identifying the maximum crucial areas of attention, organizations can make certain they’re investing inside the most impactful compliance measures.

- Quality Control Optimization

By analyzing historical quality control data, predictive analytics can:

- Critical Control Point Identification: Predictive models can examine big quantities of production statistics to become aware of the factors inside the method which have the most substantial effect on food safety. This allows for more cantered and powerful fine manage measures.

- Sampling Protocol Optimization: Analytics can help determine the best sampling frequencies and locations based totally on historic information and chance elements. This can result in more green use of checking out assets while keeping or improving protection standards.

- Predictive Maintenance: By analyzing device overall performance statistics, predictive models can count on while equipment is in all likelihood to fail or underperform, doubtlessly main to safety troubles. This lets in for proactive protection, reducing the threat of infection because of system malfunction.

Benefits of Predictive Analytics in Food Safety

- Proactive Risk Management: Shifting from reactive to proactive safety measures, permitting agencies to cope with capability troubles earlier than they escalate into fundamental troubles.

- Cost Reduction: Minimizing recollects, waste, and inefficiencies in protection methods. The Food Marketing Institute and Grocery Manufacturers Association estimate that the average cost of a do not forget for food businesses is $10 million in direct prices, no longer such as logo damage and misplaced sales.

- Enhanced Consumer Trust: Demonstrating commitment to food safety thru superior technology can improve consumer confidence. A examine by way of the Food Industry Association located that 95% of customers do not forget food protection important while making shopping decisions

- Improved Resource Allocation: Focusing efforts on the most crucial protection troubles, main to extra green use of time, personnel, and monetary resources.

- Faster Response Times: Enabling quicker identity and resolution of ability safety problems. In instances of foodborne infection outbreaks, lowering response time by even a few hours can considerably restriction the scope and impact of the incident.

- Data-Driven Decision Making: Basing safety strategies on stable, information-subsidized insights rather than intuition or previous practices.

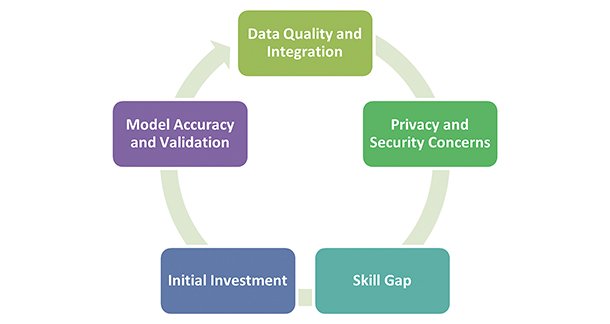

Challenges and Considerations

While predictive analytics offers significant benefits, its implementation in food safety is not without challenges:

- Data Quality and Integration: Ensuring the accuracy and compatibility of facts from diverse assets may be challenging. Food businesses regularly address facts silos and incompatible structures, making it hard to create unified information set for analysis.

- Privacy and Security Concerns: Protecting sensitive statistics whilst sharing vital facts throughout the supply chain calls for strong security features and clean information governance regulations.

- Skill Gap: Implementing and retaining predictive analytics structures requires specialized knowledge in each statistics technological know-how and food protection. Many food organizations face demanding situations in recruiting and retaining professionals with this specific skill set.

- Initial Investment: Implementing predictive analytics structures can be high priced, particularly for smaller organizations. The initial investment in generation, education, and system changes may be a massive barrier to adoption.

- Model Accuracy and Validation: Ensuring that predictive models are accurate and reliable in actual-global eventualities is an ongoing task. Models want to be continuously verified and updated to account for converting conditions and new records.

Future Trends

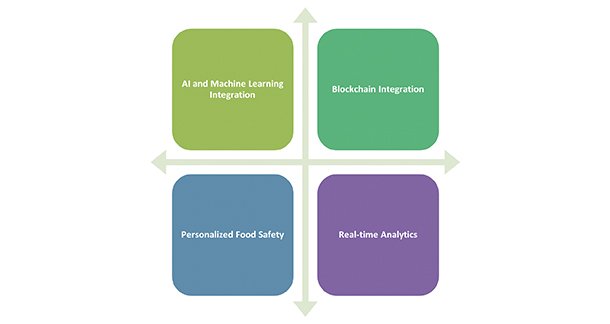

As predictive analytics in food safety continues to evolve, several trends are emerging:

- AI and Machine Learning Integration: More state-of-the-art algorithms able to handling complex, multifaceted facts are being developed. Deep learning models, for instance, can process unstructured data like images and sensor readings to detect anomalies that might indicate safety risks.

- Blockchain Integration: Combining predictive analytics with blockchain generation can decorate traceability and transparency in the course of the food supply chain. This integration can offer a stable, immutable report of food safety records, making predictive models more robust and reliable.

- Real-time Analytics: Advancements in computing strength and IoT era are transferring the enterprise toward immediately threat evaluation and decision-making talents. Real-time analytics can allow for immediate interventions while protection risks are detected.

- Personalized Food Safety: As consumer data becomes more readily available, predictive analytics may be used to tailor safety measures based on individual consumer profiles and preferences. This could lead to more targeted recalls and personalized food safety recommendations.

Conclusion

Predictive analytics is transforming the panorama of food safety, providing unprecedented talents to assume and save you risks. As the era continues to evolve, it guarantees to create a more secure, greener worldwide food device. However, figuring out this ability will require ongoing investment, collaboration, and a commitment to statistics-driven selection-making throughout the food industry.

The integration of predictive analytics with other emerging technology like AI, blockchain, and IoT is possibly to cause even more modern answers for ensuring the safety and nice of our food supply. As these technologies mature, we are able to count on to look more customized, proactive, and globally coordinated procedures to food safety management.

For food agencies, embracing predictive analytics is turning into less of an option and extra of a need to stay competitive and compliant in increasingly complicated regulatory surroundings. By leveraging the power of facts and superior analytics, companies cannot only decorate their protection protocols but also construct more trust with purchasers and regulators.

As we circulate ahead, the fulfilment of predictive analytics in food safety will depend upon addressing the challenges of data high-quality, privacy, and talents gaps. It can even require a cultural shift inside organizations to embody information-driven choice-making completely. With these factors in area, predictive analytics has the potential to revolutionize food safety, minimizing dangers and ensuring a safer food deliver for customer worldwide.

Ashutosh Jaiswal

Food Safety Professional

Email: ashuthewall@gmail.com

Website: https://www.foodsafetywithashutosh.com