As India’s food processing sector elevates its mechanisms owing to surging consumer demand, rising exports, and relentless modernization, producers must prioritize product safety and purity like never before. For manufacturers of spices, snacks, dairy, flour, grains, and ready-to-eat foods, even the slightest contamination from metal or ferrous materials can trigger costly recalls, tarnish brand reputation, and invite regulatory scrutiny. Bunting Magnetics Co. stands as the clear leader in magnetic separation and metal detection, offering robust, food-safe solutions meticulously designed to tackle these challenges head-on, ensuring product integrity, protecting equipment, and guaranteeing compliance with rigorous global food safety standards.

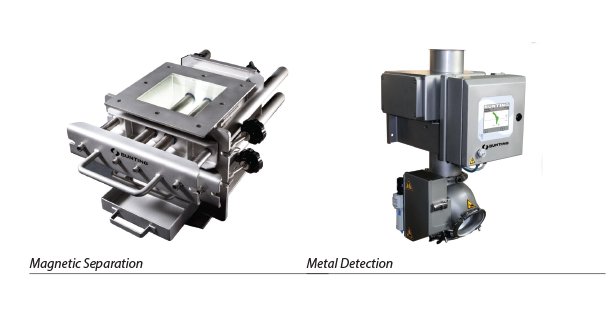

The Crucial Role of Magnetic Separation

Metal contaminants can infiltrate food from various channels, including the wear and tear of processing machinery, incoming raw materials, or during transportation and packaging. Traditional detection systems frequently fall short, especially when dealing with elusive fine ferrous particles or stainless steel fragments. This is why magnetic separation is not a choice; it’s a necessity. Bunting’s high-intensity magnetic separators are engineered to extract even the most challenging ferrous and weakly magnetic contaminants from dry, semi-dry, and liquid food products. Key systems designed for food applications include: –

- FF Drawer Filters: These gravity-fed solutions employ rare-earth magnets to capture metal contaminants from flour, sugar, and spices.

- Magnetic Liquid Traps: Tailored for viscous products such as sauces and dairy, these devices capture iron and steel particles before packaging.

- Plate and Grate Magnets: Perfectly suited for ingredients navigating chutes or hoppers. Every solution is crafted from food-grade stainless steel and features easy-clean mechanisms, with strict adherence to HACCP compliance standards.

Complete Detection and Protection

Magnetic systems are vital, but they represent only part of the solution. To achieve comprehensive control over metal contamination, Bunting integrates cutting-edge metal detectors alongside its separators. The latest Tunnel-style Metal Detectors, when paired with automated reject mechanisms, can effectively identify and eliminate ferrous, non-ferrous, and stainless steel contaminants, empowering manufacturers with unparalleled peace of mind and traceability. Combining detection with separation forms a dual-layer protection system, essential for high-risk categories such as baby food, dairy, and export-oriented production lines.

Championing the ‘Make in India’ Food Vision

Bunting has steadfastly supported Indian food manufacturers through its expert technical sales team and extensive partner network. As investments in automation and adherence to international quality standards escalate, the demand for reliable separation and detection technology is more critical than ever. Bunting are witnessing a significant uptick in Indian producers adopting Bunting’s magnetic and metal detection equipment as integral components of their food safety and export readiness strategies. They take pride in driving this transformation with our proven, easy-to-maintain systems that safeguard both products and reputations.

Thanks for this post, I am a big big fan of this site would like to go on updated.

Good day very cool website!! Guy .. Excellent .. Amazing .. I’ll bookmark your website and take the feeds additionallyKI’m glad to seek out numerous helpful info right here in the put up, we’d like develop extra strategies on this regard, thanks for sharing. . . . . .

I believe you have remarked some very interesting points, thankyou for the post.

I have read some just right stuff here. Definitely worth bookmarking for revisiting. I wonder how much attempt you place to make this kind of wonderful informative web site.

Do you mind if I quote a few of your articles as long as I provide credit and sources back to your webpage? My blog is in the very same area of interest as yours and my users would certainly benefit from a lot of the information you provide here. Please let me know if this alright with you. Thanks a lot!

I have been absent for some time, but now I remember why I used to love this website. Thank you, I’ll try and check back more frequently. How frequently you update your web site?

I love your blog.. very nice colors & theme. Did you design this website yourself or did you hire someone to do it for you? Plz answer back as I’m looking to create my own blog and would like to know where u got this from. appreciate it

Thanks a lot for giving everyone an extremely terrific chance to read from this website. It is usually so sweet plus jam-packed with a great time for me personally and my office acquaintances to search the blog at least three times weekly to see the newest things you will have. And lastly, I’m at all times satisfied with all the powerful principles served by you. Some 1 facts in this posting are in truth the very best we’ve had.

Hi, I think your site might be having browser compatibility issues. When I look at your website in Safari, it looks fine but when opening in Internet Explorer, it has some overlapping. I just wanted to give you a quick heads up! Other then that, fantastic blog!

I believe this web site holds some really superb information for everyone :D. “The public will believe anything, so long as it is not founded on truth.” by Edith Sitwell.

Some genuinely nice and useful info on this site, besides I believe the design and style has got excellent features.

Right now it seems like Drupal is the best blogging platform available right now. (from what I’ve read) Is that what you are using on your blog?

Loving the information on this site, you have done outstanding job on the posts.

I love it when people come together and share opinions, great blog, keep it up.

What i do not understood is in reality how you are no longer actually much more neatly-liked than you may be right now. You are so intelligent. You realize thus significantly in terms of this topic, produced me personally imagine it from numerous varied angles. Its like women and men aren’t involved until it is one thing to do with Woman gaga! Your personal stuffs nice. All the time take care of it up!

I like this web blog so much, saved to my bookmarks. “To hold a pen is to be at war.” by Francois Marie Arouet Voltaire.

Nice blog here! Also your site loads up fast! What web host are you using? Can I get your affiliate link to your host? I wish my web site loaded up as fast as yours lol

Hello. splendid job. I did not expect this. This is a great story. Thanks!

It’s truly a great and helpful piece of information. I am happy that you shared this useful info with us. Please stay us informed like this. Thank you for sharing.

very good post, i definitely love this website, keep on it

I will immediately take hold of your rss as I can not to find your email subscription hyperlink or newsletter service. Do you’ve any? Please allow me realize so that I may just subscribe. Thanks.

Hi! This is kind of off topic but I need some help from an established blog. Is it tough to set up your own blog? I’m not very techincal but I can figure things out pretty fast. I’m thinking about making my own but I’m not sure where to start. Do you have any ideas or suggestions? Thanks

I gotta favorite this website it seems very useful extremely helpful

fantastic submit, very informative. I wonder why the opposite specialists of this sector do not notice this. You should continue your writing. I am confident, you’ve a great readers’ base already!

What i do not realize is if truth be told how you are now not really much more well-appreciated than you might be right now. You’re very intelligent. You recognize therefore considerably relating to this topic, made me in my view imagine it from so many varied angles. Its like men and women aren’t interested except it is something to accomplish with Lady gaga! Your personal stuffs great. All the time care for it up!

Wonderful beat ! I would like to apprentice while you amend your site, how could i subscribe for a blog web site? The account helped me a acceptable deal. I had been tiny bit acquainted of this your broadcast offered bright clear idea

It’s really a nice and helpful piece of information. I am glad that you shared this helpful info with us. Please keep us up to date like this. Thanks for sharing.

You actually make it appear so easy with your presentation but I to find this topic to be actually one thing that I think I might by no means understand. It kind of feels too complicated and very extensive for me. I’m looking ahead for your next submit, I’ll try to get the hang of it!

F*ckin’ tremendous things here. I am very glad to see your post. Thanks a lot and i’m looking forward to contact you. Will you please drop me a e-mail?

I really treasure your piece of work, Great post.

Hi, Neat post. There’s a problem with your website in internet explorer, would test this… IE still is the market leader and a big portion of people will miss your excellent writing due to this problem.

Hello there, I found your site via Google while looking for a related topic, your website came up, it looks good. I have bookmarked it in my google bookmarks.

I was suggested this web site by my cousin. I’m not sure whether this post is written by him as no one else know such detailed about my problem. You’re amazing! Thanks!

Definitely, what a fantastic site and educative posts, I surely will bookmark your blog.Best Regards!

You have brought up a very superb details , thanks for the post.

Hello! I could have sworn I’ve been to this blog before but after browsing through some of the post I realized it’s new to me. Anyways, I’m definitely happy I found it and I’ll be book-marking and checking back frequently!

You really make it seem so easy with your presentation but I in finding this topic to be really one thing which I feel I might by no means understand. It sort of feels too complicated and very wide for me. I’m having a look forward to your subsequent post, I will attempt to get the cling of it!

Some really nice and utilitarian information on this web site, also I conceive the design holds good features.

This design is spectacular! You obviously know how to keep a reader entertained. Between your wit and your videos, I was almost moved to start my own blog (well, almost…HaHa!) Excellent job. I really enjoyed what you had to say, and more than that, how you presented it. Too cool!

Some really interesting details you have written.Assisted me a lot, just what I was searching for : D.

You have noted very interesting points! ps nice internet site. “Mediocrity knows nothing higher than itself, but talent instantly recognizes genius.” by Conan Doyle.

Glad to be one of several visitors on this awe inspiring website : D.

I wanted to thank you for this great read!! I definitely enjoying every little bit of it I have you bookmarked to check out new stuff you post…

Thank you for sharing excellent informations. Your web-site is very cool. I am impressed by the details that you have on this blog. It reveals how nicely you perceive this subject. Bookmarked this web page, will come back for more articles. You, my friend, ROCK! I found simply the info I already searched all over the place and simply couldn’t come across. What a perfect site.

You could definitely see your enthusiasm in the work you write. The arena hopes for more passionate writers like you who are not afraid to say how they believe. At all times go after your heart. “We are near waking when we dream we are dreaming.” by Friedrich von Hardenberg Novalis.

I am glad to be one of many visitants on this outstanding site (:, thanks for putting up.

When I initially commented I clicked the “Notify me when new comments are added” checkbox and now each time a comment is added I get four e-mails with the same comment. Is there any way you can remove people from that service? Thanks a lot!

Real excellent visual appeal on this website , I’d value it 10 10.

I got what you mean , regards for posting.Woh I am glad to find this website through google. “I was walking down the street wearing glasses when the prescription ran out.” by Steven Wright.

whoah this blog is magnificent i love reading your articles. Keep up the good work! You know, a lot of people are hunting around for this information, you could help them greatly.

Outstanding post, I believe website owners should acquire a lot from this blog its really user genial.

Hey there! I’m at work surfing around your blog from my new apple iphone! Just wanted to say I love reading your blog and look forward to all your posts! Keep up the great work!

Wow! Thank you! I always wanted to write on my website something like that. Can I include a portion of your post to my site?

Real nice layout and wonderful articles, nothing at all else we want : D.

Oh my goodness! an amazing article dude. Thank you Nonetheless I’m experiencing difficulty with ur rss . Don’t know why Unable to subscribe to it. Is there anyone getting an identical rss downside? Anybody who knows kindly respond. Thnkx

Hi, i feel that i noticed you visited my site so i came to “go back the want”.I’m attempting to find things to improve my web site!I guess its ok to use a few of your ideas!!

Thanks for helping out, fantastic information. “You must do the things you think you cannot do.” by Eleanor Roosevelt.

I gotta bookmark this site it seems handy very useful

You can definitely see your enthusiasm in the paintings you write. The world hopes for even more passionate writers such as you who are not afraid to say how they believe. Always follow your heart. “A simple fact that is hard to learn is that the time to save money is when you have some.” by Joe Moore.

Magnificent site. A lot of helpful information here. I am sending it to a few pals ans additionally sharing in delicious. And certainly, thank you for your sweat!

Hello my friend! I want to say that this post is awesome, great written and include almost all significant infos. I’d like to see more posts like this .

What i don’t realize is in fact how you’re no longer actually a lot more well-preferred than you might be now. You’re so intelligent. You understand therefore considerably in terms of this topic, produced me for my part imagine it from a lot of numerous angles. Its like women and men aren’t interested except it’s one thing to accomplish with Woman gaga! Your personal stuffs great. At all times care for it up!

Really fantastic information can be found on web blog.

An impressive share, I just given this onto a colleague who was doing a little analysis on this. And he in fact bought me breakfast because I found it for him.. smile. So let me reword that: Thnx for the treat! But yeah Thnkx for spending the time to discuss this, I feel strongly about it and love reading more on this topic. If possible, as you become expertise, would you mind updating your blog with more details? It is highly helpful for me. Big thumb up for this blog post!

Hello my friend! I want to say that this article is amazing, nice written and include almost all vital infos. I would like to see more posts like this.

This is a topic close to my heart cheers, where are your contact details though?

Whats up! I simply would like to give a huge thumbs up for the great data you’ve got right here on this post. I will probably be coming again to your weblog for more soon.

Hello there, You’ve done an excellent job. I’ll definitely digg it and personally recommend to my friends. I’m sure they’ll be benefited from this website.

Very interesting topic, appreciate it for posting. “He who seizes the right moment is the right man.” by Johann Wolfgang von Goethe.

I’m still learning from you, as I’m improving myself. I certainly love reading all that is posted on your site.Keep the aarticles coming. I liked it!

Some truly excellent info , Gladiolus I detected this.

Excellent weblog right here! Also your site rather a lot up fast! What web host are you the use of? Can I get your affiliate hyperlink to your host? I wish my web site loaded up as quickly as yours lol

Nearly all of whatever you point out is supprisingly accurate and it makes me wonder why I had not looked at this with this light before. This particular piece really did turn the light on for me as far as this particular issue goes. Nonetheless at this time there is actually one issue I am not really too cozy with so whilst I attempt to reconcile that with the actual central idea of the issue, let me observe what all the rest of your readers have to say.Very well done.

There are definitely quite a lot of particulars like that to take into consideration. That is a great point to convey up. I supply the thoughts above as general inspiration however clearly there are questions just like the one you deliver up the place a very powerful thing will likely be working in honest good faith. I don?t know if greatest practices have emerged around things like that, however I’m sure that your job is clearly identified as a good game. Both boys and girls really feel the impression of only a moment’s pleasure, for the rest of their lives.

I conceive other website proprietors should take this web site as an model, very clean and good user genial layout.

You got a very great website, Gladiola I found it through yahoo.

Its great as your other posts : D, regards for putting up. “Say not, ‘I have found the truth,’ but rather, ‘I have found a truth.'” by Kahlil Gibran.

Thanks for any other informative site. Where else may I get that type of information written in such an ideal manner? I have a venture that I am simply now running on, and I’ve been on the look out for such info.

I am often to blogging and i really appreciate your content. The article has really peaks my interest. I am going to bookmark your site and keep checking for new information.

Wow! Thank you! I continually wanted to write on my blog something like that. Can I take a fragment of your post to my website?

Good write-up, I am normal visitor of one?¦s web site, maintain up the nice operate, and It’s going to be a regular visitor for a lengthy time.

I got what you mean , regards for posting.Woh I am happy to find this website through google.

Magnificent web site. A lot of useful info here. I’m sending it to a few pals ans also sharing in delicious. And certainly, thank you in your effort!

Hello! Someone in my Myspace group shared this website with us so I came to give it a look. I’m definitely loving the information. I’m bookmarking and will be tweeting this to my followers! Great blog and amazing style and design.

F*ckin’ awesome things here. I am very glad to look your article. Thanks so much and i’m having a look ahead to contact you. Will you please drop me a e-mail?

You are my breathing in, I own few blogs and very sporadically run out from to post .

Heya i am for the first time here. I found this board and I find It truly useful & it helped me out much. I hope to provide one thing again and aid others like you helped me.

Greetings! I know this is kinda off topic but I was wondering if you knew where I could locate a captcha plugin for my comment form? I’m using the same blog platform as yours and I’m having trouble finding one? Thanks a lot!

bingoplus ph refers to the Philippine-facing version of Bingo Plus, tailored for users located in the Philippines.

I don’t normally comment but I gotta admit appreciate it for the post on this amazing one : D.

I liked as much as you will obtain performed right here. The comic strip is tasteful, your authored subject matter stylish. however, you command get bought an nervousness over that you would like be handing over the following. ill indisputably come more earlier again since precisely the similar nearly a lot ceaselessly inside of case you protect this hike.

But wanna comment that you have a very decent web site, I love the design and style it actually stands out.

Somebody essentially help to make seriously articles I might state. This is the very first time I frequented your website page and thus far? I surprised with the research you made to make this particular publish incredible. Wonderful job!

Everything is very open and very clear explanation of issues. was truly information. Your website is very useful. Thanks for sharing.

I am not sure where you are getting your information, but good topic. I must spend a while studying more or understanding more. Thank you for magnificent info I was in search of this information for my mission.

I like this site very much, Its a rattling nice berth to read and get information.

I have been absent for a while, but now I remember why I used to love this website. Thank you, I’ll try and check back more frequently. How frequently you update your web site?

Hello my friend! I want to say that this article is awesome, great written and come with almost all significant infos. I’d like to see more posts like this.

I’ve been browsing online greater than 3 hours lately, yet I never discovered any interesting article like yours. It is beautiful price sufficient for me. In my view, if all site owners and bloggers made just right content material as you did, the internet can be much more helpful than ever before.

Just what I was looking for, appreciate it for putting up.

so much excellent info on here, : D.

Undeniably believe that which you said. Your favorite justification seemed to be on the net the simplest thing to be aware of. I say to you, I certainly get annoyed while people think about worries that they plainly don’t know about. You managed to hit the nail upon the top as well as defined out the whole thing without having side effect , people could take a signal. Will likely be back to get more. Thanks

Thanks a lot for sharing this with all of us you actually know what you are talking approximately! Bookmarked. Please additionally consult with my site =). We may have a link change agreement between us!

Thank you for sharing excellent informations. Your web-site is very cool. I’m impressed by the details that you¦ve on this website. It reveals how nicely you perceive this subject. Bookmarked this web page, will come back for more articles. You, my pal, ROCK! I found just the information I already searched everywhere and just could not come across. What a perfect web site.

That is the fitting weblog for anyone who needs to find out about this topic. You notice so much its nearly exhausting to argue with you (not that I really would need…HaHa). You undoubtedly put a new spin on a topic thats been written about for years. Great stuff, simply nice!

Rattling great visual appeal on this website , I’d value it 10 10.

Hiya! Quick question that’s entirely off topic. Do you know how to make your site mobile friendly? My site looks weird when viewing from my apple iphone. I’m trying to find a template or plugin that might be able to correct this problem. If you have any suggestions, please share. Cheers!

Hi my family member! I wish to say that this post is amazing, great written and include almost all important infos. I?¦d like to peer more posts like this .

Generally I do not learn article on blogs, but I would like to say that this write-up very forced me to try and do so! Your writing style has been amazed me. Thanks, quite great post.

I as well believe so , perfectly written post! .

What’s Going down i am new to this, I stumbled upon this I’ve found It positively useful and it has aided me out loads. I hope to contribute & aid different customers like its aided me. Great job.

Great line up. We will be linking to this great article on our site. Keep up the good writing.

Hiya, I’m really glad I’ve found this information. Today bloggers publish only about gossips and net and this is really frustrating. A good blog with exciting content, this is what I need. Thanks for keeping this web-site, I will be visiting it. Do you do newsletters? Can’t find it.