In conversation with Bryan Machado, Founder of Navin Plast, we discuss the packaging innovations at Navin Plast , the science behind the same, their upcoming new launch “cake in a box”, sustainability practices, and more.

Question- Tell us in brief about the processes that go into creating presentable plastic packaging for bakery products , especially cakes.

The process of designing plastic packaging for bakery products, including cakes, follows a structured approach. First, we identify the problem or need within the bakery or food industry. Since, food businesses are constantly experimenting with new dishes and portion sizes, packaging must evolve accordingly.

Once the requirements are clear, we create a digital design of the packaging. A prototype is then developed and tested with the bakery to ensure it meets their needs. If the prototype is successful, we proceed to manufacturing the molds, which can take anywhere from 45 to 75 days depending on the complexity of the product.

Question– Are cake boxes only targeted to established commercial bakeries? What is the minimum MOQ required? Can they be customized as per the brand guidance?

No, cake boxes are not limited to commercial bakeries. They are also used for packaging chocolates, cookies, biscuits, nuts, mithai and other food products.

For customization, if a client requires large quantities or branding, we can engrave their name or logo on the boxes. For smaller orders, branding can be done using stickers, ribbons, and other decorative elements. The Minimum Order Quantity (MOQ) varies based on the product. Our online orders cater to smaller customers and offline orders are sold in wholesale.

Question– How do you differentiate plastic box packaging based on product type like tiramisu or mousse or black forest? What value does box packaging add to the overall product presentation? How does it affect the costing for bakeries?

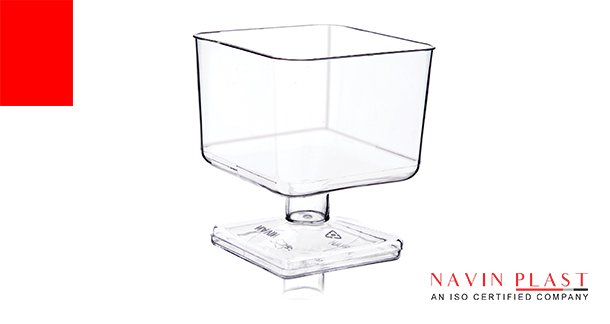

Packaging is chosen based on product type and size. For example, tiramisu is typically served in a 100ml plastic cup. Chocolate mousse is often served in a 60ml plastic cup. The right packaging enhances product presentation significantly. Imagine a multi-layered cake packed in an opaque paper cup. Customers would not be able to appreciate its layers and texture. However, in a transparent plastic cup, they can see the layers, making the product more visually appealing and increasing sales.

While plastic cups may cost around 30% more than paper cups, they justify a higher selling price by offering better presentation, which attracts more customers and boosts revenue for bakeries.

Question– Paper or cardboard boxes are commonly used in cake packaging. What difference are you trying to offer with ‘cake in a box’ packaging? Quick commerce is the new e- commerce now. What edgedoes your box packaging have compared to others?

We were the first ones to get the concept cake in the box. Traditionally, cakes are sold either as whole cakes by weight (kgs) or as single-serving pastries. While pastries work well for individuals, there was a gap in the market for those who wanted to share a cake with 2-3 people without buying a full-sized one. This gap led to the creation of “Cake in a Box” a convenient perfectly portioned option for small groups.

Over time, this packaging has proven to be versatile. Now, it is being used not just for cakes but also for chocolates, dry fruits, and sweets, making it a practical and attractive choice for various treats.

Question– Sustainability and plastic do not go together for the most part. Could you explain the rational of using box packaging?

The reason Plastic was Invented was that it would be eco – friendly. Paper Cups, Paper Straw, Wooden Cutlery do not fit into that paradigm. The only reason for them to be called eco – friendly is because they decompose after some time. However, if you are aware of the process, you will not identify these products as eco- friendly.

Plastics have a very good environmental profile. Only 4% of the world’s oil production is used for plastics and much less energy is used to produce it compared to other materials. Plastics are durable yet lightweight and thus, save weight in cars, aircraft, packagin,g and pipework.

So, we need to recycle the product after its specific use. Plastic can be recycled N number of times. The problem arises when the same is not disposed off in the right manner. If we can recycle 90 Percent of the product, this problem will never arise. With our brand, we request consumers to reuse and recycle the Product. Our quality is so good that they can be used to store variety of other things. Even, when we want to throw the Product it needs to be disposed off in the recycle bin. The circular plastics economy is about recognising and capturing the value of plastics as a resource, with the least impact on the climate