grow rapidly. They are extremely easy for consumers to handle and

manufacturers benefit from lower material costs.

Compared to conventional portion cups for UHT milk, they can reduce a

manufacturer’s packaging material requirements by up to 50% – the

carbon footprint is greatly improved and the impact on the environment

is reduced. In addition, stick pack packaging has a positive effect on

transport volume (50% more packaging for the same packaging volume

compared to portion cups) and transport weight. Additionally the stick

packs can be packed in decorative boxes and presented accordingly in

the supermarket.

These are the reasons why Slovakia’s dairy company has chosen this

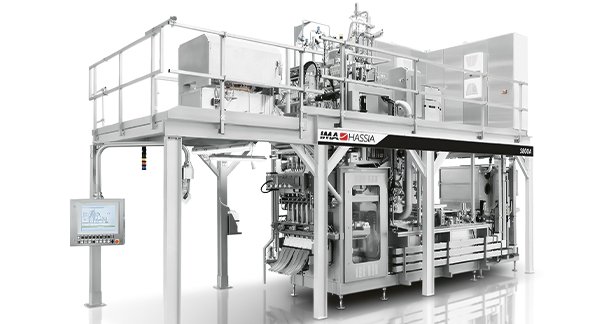

consumer-friendly packaging. The machine runs in 2-shift operation with

12 lanes and produces 36,000 stick packs per hour.

The machine sterilizes the flat foil on all sides using active packaging

degermination (germs eradicated >log 5) and feeds it into the sterile

area. Cutters then notch the foil in strips through to the seal layer. The

packaging is subsequently formed into duplex stick packs under sterile

conditions using a special forming shoulder and then sealed on three

sides. Lastly the stick packs are filled with UHT milk, also in the sterile

area, using dosing equipment specific to the product.

Different kind of UHT milk: whole milk, semi skimmed milk, lactose free

milk, and coffee cream are sold under the name ‘MINIMILK’. The latest

product innovation is a plant-based oat drink in this variant under the

name ‘MINIOAT’. All varieties are packaged in a 10 ml format; the

manufacturer plans to expand the range to include a 7 ml format as

well. To broaden market opportunities, the dairy company has also

initiated the Halal certification process.

The practical stick packs are an ideal solution for offices, hotels, cafés,

fast-food chains, trains and buses as well as on-the-go. It will come in

handy at conferences, events and all types of social occasions where

warm drinks are being served with no refrigeration options available.

“We are very satisfied with the consumer friendly packaging solution this

machine offers for our UHT milk” reported Tibor Balogh, CEO of

Euromilk. “Thanks to the new packaging, milk and cream coming from

local farms find a way to even more people, and thanks to it we can

fulfil our mission to ensure that what is good remains good.”

MINIMILK is liquid milk or coffee cream of high quality. It’s not dried

milk extract, but truly delicious milk and cream from Rye Island—a

region nestled between the Danube and the Little Danube in southern

Slovakia.