In laboratories worldwide, a quiet transformation is taking place. Once defined by manual processes and paper records, the modern lab is now a highly digitized, intelligent environment where data flows seamlessly from instruments to decision-makers in real time.

Yet, for much of the 20th century, laboratories remained manual, fragmented, and highly dependent on human oversight. Results often took days to generate and even longer to verify. But the 21st century has ushered in a quiet revolution—driven by data, digitization, and automation. Today’s labs are smarter, faster, and more integrated than ever before. From AI-powered instruments to real-time microbial detection, the transformation is redefining what laboratories can do—and how quickly they can do it.

l A Brief Look Back: Traditional Lab Tools and Their Limitations

For decades, laboratory workflows followed a largely manual and linear process. Analysts received samples, logged them in paper notebooks or spreadsheets, prepared them by hand, and operated standalone instruments that offered little in the way of integration or data capture.

Microbiological testing depended heavily on culture-based methods—incubating agar plates for up to 120 hours to assess microbial growth. Analytical chemistry relied on instruments like pH meters, titrators, or spectrophotometers that required calibration and interpretation by skilled personnel. Data transfer was a matter of printing results and retyping them into reports.

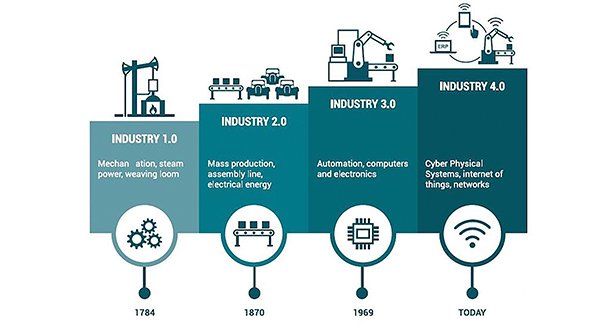

l Industry 4.0 – The Lab Joins the Smart Manufacturing Revolution

As industries move into the era of Industry 4.0, laboratories are becoming critical players in the digital value chain. Often described as the “Fourth Industrial Revolution,” Industry 4.0 emphasizes the integration of cyber-physical systems, IoT, cloud computing, and AI to create smart, self-optimizing environments.

In the laboratory context, this means:

- IoT-enabled instruments that share real-time performance data

- Cloud-based LIMS platforms that integrate with ERP and MES systems

- Predictive analytics that guide testing strategies and equipment maintenance

- Digital twins of lab processes for simulation, optimization, and remote troubleshooting

For example, a food manufacturing company using Industry 4.0 principles might link its production line with lab data so that if an online monitor detects a pH deviation or microbial risk, both the product flow and lab testing protocols adjust automatically.

Here a few examples of Digital laboratory

1. LIMS – The Lab’s Digital Brain

Imagine never losing sample or misplacing test data again. That’s the peace of mind LIMS offers.

The Laboratory Information Management System (LIMS) is one of the most transformative technologies to enter the lab environment. What began as a digital sample tracking tool has evolved into a comprehensive data and workflow management system—centralizing laboratory operations under one unified digital platform.

Why Labs Need LIMS?

A LIMS is like a google maps for your samples- it tracks where they’ve been, where they are, and where they’re going. LIMS offers critical benefits:

- Sample Tracking: From sample login to disposal, every step is recorded. You know exactly what was tested, by whom, when, and how.

- Instrument Integration: LIMS can be connected to instruments like HPLC, GC, Weighing balances, and spectrophotometers to directly import data—eliminating manual entry errors.

- Quality Control: It supports calibration reminders, preventive maintenance tracking, and control charting, ensuring your lab meets ISO, FDA, and GMP standards.

- Audit Trails: Every change in the system is logged, offering transparency and traceability for audits or investigations.

- Report Generation: Customized, automated reports for clients, regulators, or internal QA teams make communication seamless.

2. Rapid Microbiology – Speed Meets Precision

Traditional microbiology methods, although scientifically sound, are inherently slow. Waiting 3–5 days for microbial results is no longer feasible in industries that demand fast product release, real-time risk assessment, or early contamination detection. Enter Rapid Microbiological Methods (RMMs)—a suite of technologies designed to detect, quantify, and identify microorganisms faster and more reliably.

Benefits of Rapid Micro Tools:

- Faster release of products (especially in pharma & food).

- Real-time contamination alerts during production.

- Integration with LIMS enables instant result logging, tracking, and trend analysis.

- Enhanced compliance with international guidelines.

3. SCADA and Online Monitoring – Real-Time Control Beyond the Bench

As laboratory operations extend beyond the test bench to include environmental and utility monitoring, SCADA (Supervisory Control and Data Acquisition) systems have become essential. Originally designed for industrial process control, SCADA systems are now fully integrated into advanced laboratory and manufacturing environments.

SCADA platforms continuously monitor critical parameters such as:

- Cleanroom pressure differentials

- Humidity and temperature

- Conductivity and TOC

- Compressed gas supply and flow

SCADA is most powerful when integrated with LIMS and Building Management Systems (BMS). This integration ensures that environmental data affecting test conditions are traceable alongside analytical results, fulfilling regulatory expectations for control and documentation.

4. Mobile Testing Labs – Taking Quality to the Field

In India, the Food Safety and Standards Authority of India (FSSAI) has introduced an innovative step in public health protection through mobile food testing laboratories, often referred to as Food Safety on Wheels. These mobile labs are equipped with basic chemical and microbiological testing tools to detect common food adulterants—right on the spot.

Each mobile unit includes:

- Basic rapid test kits for contaminants like pesticides, formalin, and artificial colors

- Facilities for microbiological testing of water and food samples

- Interactive displays and educational materials for community awareness

Beyond testing, these units also act as outreach vehicles, helping educate vendors, students, and consumers about food safety and hygiene.

As mobile lab technology improves, there’s growing potential to integrate LIMS, GPS tracking, and real-time data transmission into these units—turning them into powerful surveillance tools for remote and underserved areas.

FSSAI’s mobile lab initiative illustrates how lab technology is no longer confined to the lab—it’s now rolling across streets, markets, and festivals, ensuring food safety at the grassroots level.

- The Digital Revolution Behind Faster, Safer, and Smarter Testing

Robotic platforms are increasingly used for sample preparation, weighing, dilution, and reagent handling—operations traditionally vulnerable to human error. These systems improve consistency and are especially beneficial in high-throughput environments such as pharmaceutical QC labs or genomic research centers.

Moreover, AI-powered software tools are emerging that analyze raw data to detect trends, outliers, and potential data integrity issues before they become critical. Instead of relying solely on human interpretation, laboratories can now lean on intelligent systems for faster, more consistent, and auditable results.

This convergence of hardware and AI enhances both efficiency and reliability, ensuring that complex analytical work meets the highest standards of precision without compromising throughput or compliance.

This end-to-end integration brings several benefits:

- Reduced turnaround time from sample receipt to report generation

- Improved data integrity by minimizing manual intervention

- Real-time visibility across operations, instruments, and environments

- Regulatory readiness through full traceability and audit trails

The result is a lab that no longer functions in silos, but as a coordinated digital ecosystem, capable of making decisions, detecting risks, and supporting compliance at every step.

l Conclusion – A Smarter Lab for a Safer World

The laboratory has undergone a remarkable transformation. What once depended on manual processes, paper records, and isolated instruments is now driven by interconnected systems, artificial intelligence, and real-time monitoring. This evolution is not just about efficiency—it’s about safety, accuracy, traceability, and public trust.

Whether testing drinking water, verifying pharmaceutical purity, or ensuring food safety, today’s advanced laboratory infrastructure enables faster decisions, fewer errors, and greater compliance. LIMS, rapid microbiology platforms, smart instruments, and SCADA systems are no longer luxuries—they are essential tools in the pursuit of quality and safety.

As technology continues to advance, laboratories will become even more intuitive, intelligent, and integrated. In this future, science will not only move faster—it will move smarter.

About The Author

|

Author Ashutosh Jaiswal Food Safety Professional Email: ashuthewall@gmail.com Website: https://www.foodsafetywithashutosh.com |

|

Author Ayushi Shukla Food Safety Professional Email: ayushishukla2223@gmail.com |

I was just searching for this info for a while. After six hours of continuous Googleing, finally I got it in your website. I wonder what’s the lack of Google strategy that do not rank this type of informative sites in top of the list. Usually the top sites are full of garbage.

Hey There. I found your blog using msn. This is a really well written article. I’ll be sure to bookmark it and come back to read more of your useful info. Thanks for the post. I will definitely comeback.

I am really impressed with your writing skills as well as with the layout on your weblog. Is this a paid theme or did you modify it yourself? Either way keep up the excellent quality writing, it’s rare to see a nice blog like this one today..

I discovered your blog site on google and check a few of your early posts. Continue to keep up the very good operate. I just additional up your RSS feed to my MSN News Reader. Seeking forward to reading more from you later on!…

I¦ve read several good stuff here. Certainly price bookmarking for revisiting. I surprise how much attempt you set to create this kind of wonderful informative site.

I’m not sure where you’re getting your information, but good topic. I needs to spend some time learning much more or understanding more. Thanks for excellent info I was looking for this information for my mission.

Appreciate it for all your efforts that you have put in this. very interesting info .

Fantastic web site. Plenty of useful information here. I am sending it to some buddies ans additionally sharing in delicious. And of course, thanks for your effort!

We are a group of volunteers and opening a new scheme in our community. Your site provided us with valuable info to work on. You’ve done a formidable job and our entire community will be thankful to you.

Hi there! I just would like to give a huge thumbs up for the good info you’ve right here on this post. I can be coming again to your blog for more soon.

I am often to blogging and i really appreciate your content. The article has really peaks my interest. I am going to bookmark your site and keep checking for new information.

I conceive this site has very wonderful pent content blog posts.

Hello just wanted to give you a quick heads up. The text in your content seem to be running off the screen in Safari. I’m not sure if this is a format issue or something to do with web browser compatibility but I figured I’d post to let you know. The design look great though! Hope you get the issue solved soon. Kudos

You completed several nice points there. I did a search on the matter and found nearly all persons will go along with with your blog.

I intended to put you this little bit of remark in order to say thanks yet again on the incredible things you have contributed in this article. It was certainly particularly open-handed of you to provide unreservedly exactly what a few individuals could possibly have supplied for an electronic book to earn some profit for themselves, most importantly since you might have tried it in case you considered necessary. The thoughts in addition worked like the fantastic way to know that some people have a similar keenness like my own to grasp more concerning this problem. I’m sure there are thousands of more pleasurable opportunities in the future for folks who read through your blog post.

Lovely just what I was searching for.Thanks to the author for taking his clock time on this one.

I have read several good stuff here. Certainly worth bookmarking for revisiting. I wonder how much effort you put to create such a fantastic informative site.

I want foregathering useful information , this post has got me even more info! .

Woh I enjoy your articles, bookmarked! .

Wonderful work! This is the type of info that should be shared around the internet. Shame on the search engines for not positioning this post higher! Come on over and visit my site . Thanks =)

Very nice post. I just stumbled upon your blog and wanted to say that I’ve truly enjoyed surfing around your blog posts. In any case I will be subscribing to your feed and I hope you write again soon!

Hey would you mind letting me know which hosting company you’re working with? I’ve loaded your blog in 3 different internet browsers and I must say this blog loads a lot quicker then most. Can you suggest a good hosting provider at a reasonable price? Thank you, I appreciate it!

you have a great blog here! would you like to make some invite posts on my blog?

he blog was how do i say it… relevant, finally something that helped me. Thanks

This actually answered my downside, thank you!

Really enjoyed this blog post, can I set it up so I get an update sent in an email whenever there is a fresh update?

You really make it seem so easy with your presentation but I find this matter to be really something which I think I would never understand. It seems too complicated and very broad for me. I’m looking forward for your next post, I’ll try to get the hang of it!

The next time I read a blog, I hope that it doesnt disappoint me as much as this one. I mean, I know it was my choice to read, but I actually thought youd have something interesting to say. All I hear is a bunch of whining about something that you could fix if you werent too busy looking for attention.

There is noticeably a bunch to realize about this. I believe you made various nice points in features also.

I like what you guys are up too. Such intelligent work and reporting! Carry on the excellent works guys I?¦ve incorporated you guys to my blogroll. I think it will improve the value of my website 🙂

I’ve read several excellent stuff here. Certainly price bookmarking for revisiting. I surprise how so much attempt you put to make this sort of magnificent informative web site.

I do not even know how I ended up here, but I thought this post was good. I do not know who you are but certainly you are going to a famous blogger if you are not already 😉 Cheers!

There is noticeably a bundle to know about this. I assume you made certain nice points in features also.

I’m no longer certain the place you are getting your info, however great topic. I needs to spend some time studying more or figuring out more. Thank you for excellent info I used to be in search of this information for my mission.

Hello! Do you use Twitter? I’d like to follow you if that would be okay. I’m undoubtedly enjoying your blog and look forward to new updates.

Hello. remarkable job. I did not anticipate this. This is a great story. Thanks!

Hey there! I’m at work browsing your blog from my new iphone 4! Just wanted to say I love reading through your blog and look forward to all your posts! Keep up the great work!

Those are yours alright! . We at least need to get these people stealing images to start blogging! They probably just did a image search and grabbed them. They look good though!

Simply want to say your article is as astonishing. The clearness in your post is simply great and i could assume you’re an expert on this subject. Well with your permission allow me to grab your RSS feed to keep up to date with forthcoming post. Thanks a million and please keep up the gratifying work.

We are a gaggle of volunteers and opening a new scheme in our community. Your website provided us with helpful information to work on. You have done a formidable activity and our entire neighborhood will probably be grateful to you.

I have read some just right stuff here. Certainly worth bookmarking for revisiting. I surprise how so much effort you place to create the sort of fantastic informative website.

I envy your piece of work, thanks for all the good blog posts.

Dead written subject material, Really enjoyed looking at.

Great post. I was checking constantly this blog and I’m impressed! Extremely helpful information specially the last part 🙂 I care for such info a lot. I was looking for this certain info for a very long time. Thank you and good luck.

The very core of your writing whilst sounding reasonable at first, did not sit properly with me after some time. Somewhere throughout the paragraphs you actually managed to make me a believer unfortunately just for a short while. I still have got a problem with your leaps in logic and one would do nicely to help fill in those breaks. When you actually can accomplish that, I will definitely end up being amazed.

Definitely, what a fantastic site and educative posts, I surely will bookmark your website.Best Regards!

I got what you intend,saved to my bookmarks, very nice internet site.

you’re really a good webmaster. The site loading speed is amazing. It seems that you are doing any unique trick. Moreover, The contents are masterpiece. you’ve done a magnificent job on this topic!

I like what you guys are up also. Such smart work and reporting! Carry on the excellent works guys I have incorporated you guys to my blogroll. I think it will improve the value of my site :).

I’ve read a few good stuff here. Certainly value bookmarking for revisiting. I wonder how much effort you set to make this kind of magnificent informative web site.

I’ve learn a few just right stuff here. Definitely value bookmarking for revisiting. I surprise how much attempt you put to create this type of excellent informative web site.

I was just searching for this info for a while. After six hours of continuous Googleing, finally I got it in your website. I wonder what is the lack of Google strategy that do not rank this type of informative web sites in top of the list. Normally the top sites are full of garbage.

Some really nice stuff on this site, I love it.

I truly treasure your work, Great post.

Nice post. I was checking continuously this blog and I’m impressed! Extremely useful information particularly the last part 🙂 I care for such information a lot. I was looking for this certain information for a very long time. Thank you and best of luck.

fantastic points altogether, you simply won a brand new reader. What might you suggest in regards to your post that you simply made some days in the past? Any certain?

I have been exploring for a bit for any high quality articles or weblog posts on this sort of house . Exploring in Yahoo I eventually stumbled upon this web site. Studying this information So i¦m glad to express that I’ve an incredibly just right uncanny feeling I discovered just what I needed. I so much no doubt will make sure to do not overlook this web site and provides it a look regularly.

Regards for all your efforts that you have put in this. very interesting info .

I don’t even know how I ended up here, but I thought this post was good. I don’t know who you are but definitely you are going to a famous blogger if you aren’t already 😉 Cheers!

Very interesting information!Perfect just what I was looking for!

NuStar Online Casino Login and Registration using a mobile number provides an alternative access method for users. This approach is designed to simplify the registration process by allowing users to verify and access their accounts through a mobile-based system.

Thank you for some other informative blog. The place else may I am getting that type of info written in such a perfect approach? I’ve a mission that I am just now running on, and I’ve been on the look out for such information.