Offered at no additional cost over Kollmorgen’s earlier SFD models, this encoder offers four times

greater positioning accuracy and uses energy-harvesting technology to track absolute multi-turn

positioning even when the system is powered off.

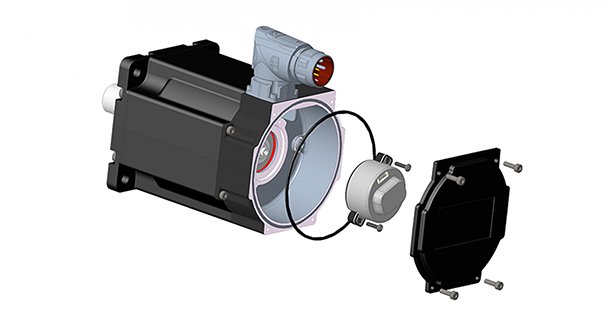

RADFORD, VA., March 25, 2025— Kollmorgen, a global leader in motion control and automation

systems, today introduced the new SFD-M (Smart Feedback Device, Multi-Turn). It allows machine

builders to achieve high-resolution multi-turn feedback with absolute positioning information

available at system startup.

Designed to work with AKDTM and AKD2G drives, the SFD-M absolute multi-turn encoder can be

integrated into Kollmorgen housed servo motors at no additional charge compared to the SFD-3

single-turn absolute encoder, providing multi-turn performance, four times greater positioning

accuracy and fifty times lower EMF noise.

Comparable third-party encoders come with a premium price. With the SFD-M, customers can

achieve substantial savings in machine designs that perform at the highest levels of precision,

efficiency and effectiveness.

Absolute multi-turn positioning for precise, productive motion

The SFD-M measures the position of the rotor shaft throughout each 360º rotation without requiring

reference to a home position, and it registers the total number of rotations the shaft has made in

either direction.

This absolute multi-turn positioning capability is ideal when precise tracking of position is required

over large rotational distances, such as in machine tool positioning, packaging machines, material

handling, satellite tracking and many other applications.

Additionally, the SFD-M maintains absolute positioning information in real time even when the system

is powered down, eliminating the need for time-consuming homing sequences upon startup.

Energy-harvesting technology for battery-free operation

Absolute multi-turn encoders from other providers often require a battery to retain positioning

information when the system is powered down or during a power failure. These external batteries

require replacement and can be subject to failure. Other alternatives use mechanical gear trains,which are noisy, backlash-prone and add size to the motor.

The new Kollmorgen SFD-M eliminates these issues, instead using energy-harvesting technology to

reliably maintain positioning information with no need for batteries or gear trains. Battery-free

operation eliminates maintenance issues while also supporting efforts to reduce the consumption of

natural resources and minimize waste.

Exceptional performance at an exceptional value

The SFD-M is highly accurate, offering these key specifications:

● Resolution

o 24 bits per revolution

o 16,777,216 counts per revolution

o 0.0772 arc-sec per count

● Multi-turn absolute range

o 16 bits = 65,536 motor revolutions

● Accuracy

o < +/– 1 arc-min typical at 25ºC

o < +/– 3 arc-min worst case

“Our new SFD-M encoder provides multi-turn absolute functionality with exceptional position

accuracy and resolution at zero additional cost over Kollmorgen motors with single-turn encoders,”

said Chris Cooper, Kollmorgen’s Senior Director of Global Product Management.

“That’s a huge benefit for precision and productivity at a savings of hundreds of dollars per motor and

potentially several thousand dollars in a complex, multi-axis machine. Single motor-to-drive cable

technology with auto drive setup further lowers total costs. We are very proud to offer all of these

benefits to our customers as an integral part of Kollmorgen’s industry-leading servo systems.”[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section]