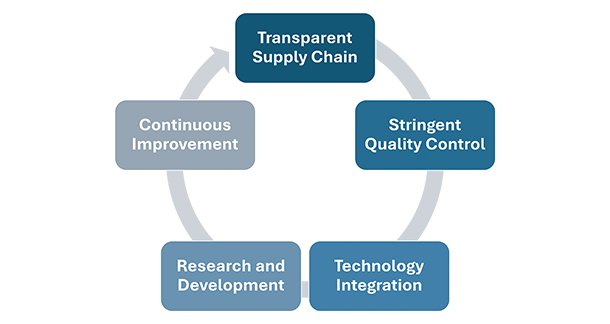

Ensuring food safety and public health is an ongoing challenge that requires constant vigilance and innovation. In the face of rising global food demand and complex supply chains, it is imperative to implement robust systems that guarantee the safety and quality of food products. This article outlines a comprehensive roadmap for enhancing food safety through transparent supply chains, stringent quality control, technology integration, research and development, and continuous improvement.

1. Transparent Supply Chain

Implement and Promote Transparent Supply Chains

A transparent supply chain is crucial for tracing the origin of food products and ensuring their safety. By promoting transparency, every stakeholder in the supply chain—from farmers to consumers—can access vital information about the journey of food items. This visibility helps in identifying and addressing any potential issues that may arise during production, processing, or distribution.

In a traditional supply chain, information is often siloed, with each participant having access only to a limited subset of data. This lack of transparency can lead to inefficiencies and vulnerabilities, such as delayed responses to contamination events or fraud. By contrast, a transparent supply chain fosters collaboration and accountability. For instance, if a contamination issue arises, it can be swiftly traced back to its source, allowing for prompt corrective action and minimizing the impact on public health.

Utilize Technology, such as Blockchain

Blockchain technology is revolutionizing the food industry by providing an immutable ledger for real-time tracking and monitoring of food items from farm to table. This technology ensures that every transaction and movement of food products are recorded and accessible, enabling stakeholders to trace the origin and history of the items. Blockchain not only enhances transparency but also builds trust among consumers, who can verify the authenticity and safety of the food they consume.

2. Stringent Quality Control

Establish Rigorous Quality Control Measures

To ensure the highest standards of food safety, it is essential to establish rigorous quality control measures at every stage of food production. These measures include implementing standardized procedures for handling, processing, and storing food products. Quality control should be an integral part of the entire supply chain, from the initial production stages to the final delivery to consumers.

Quality control begins at the farm, where good agricultural practices (GAP) should be implemented to minimize the risk of contamination. These practices include proper handling of fertilizers and pesticides, ensuring that water used for irrigation is safe, and maintaining sanitary conditions during harvesting. For instance, farmers should use clean and sanitized equipment, and personal hygiene practices should be strictly followed to prevent contamination.

During processing, standardized procedures should be in place to prevent contamination and ensure consistency. This includes regular cleaning and sanitization of equipment, proper handling and storage of raw materials, and adherence to processing protocols.

In the distribution stage, quality control measures include maintaining proper storage conditions, such as temperature and humidity, to prevent spoilage and contamination. This is especially important for perishable items like fresh produce and dairy products, which require refrigeration to maintain their quality and safety.

Regularly Conduct Inspections and Audits

Regular inspections and audits are critical for ensuring compliance with food safety standards. By conducting frequent and thorough inspections, potential risks can be identified and mitigated before they lead to foodborne illnesses or other safety concerns. Audits help in verifying that all stakeholders adhere to established protocols and guidelines, maintaining the integrity of the food supply chain.

Inspections and audits should be conducted by trained professionals who can identify potential hazards and assess compliance with safety standards. This includes checking for proper sanitation practices, verifying that equipment is properly maintained, and ensuring that employees are following safety protocols. For example, inspectors may assess whether food handling practices comply with established hygiene standards and whether storage conditions meet safety requirements.

Third-party audits can provide an additional layer of assurance. These audits, conducted by independent organizations, assess compliance with industry standards and best practices. They can help identify gaps in safety protocols and provide recommendations for improvement. By participating in third-party audits, companies demonstrate their commitment to food safety and build trust with consumers and regulators.

3. Technology Integration

Embrace Innovative Technologies like IoT and AI

The integration of innovative technologies such as the Internet of Things (IoT) and Artificial Intelligence (AI) can significantly enhance food safety. IoT devices, including smart sensors and monitoring systems, can provide real-time data on various parameters such as temperature, humidity, and contamination levels. AI algorithms can analyze this data to detect potential food safety hazards early, allowing for timely interventions.

IoT devices can be placed throughout the supply chain to monitor conditions and provide real-time alerts if any deviations occur. For example, sensors in refrigerated trucks can monitor temperature and humidity levels, ensuring that perishable items are stored under optimal conditions. If a problem is detected, such as a rise in temperature, an alert can be sent to supply chain managers, allowing them to take corrective action before the food is compromised.

AI can enhance food safety by analyzing data from IoT devices and other sources to identify patterns and predict potential hazards. For example, AI algorithms can analyze historical data on temperature fluctuations, transportation routes, and contamination incidents to predict when and where issues are likely to occur. This predictive capability allows for proactive interventions, reducing the risk of foodborne illnesses.

Implement Smart Sensors and Monitoring Systems

Smart sensors and monitoring systems are essential tools for ensuring food quality and safety in real-time. These technologies can continuously monitor the conditions under which food products are stored and transported, providing immediate alerts if any deviations occur. This real-time monitoring helps in maintaining optimal conditions for food items, reducing the risk of spoilage and contamination.

For instance, smart sensors can monitor the temperature and humidity of storage facilities, ensuring that conditions remain within safe limits. If a deviation is detected, the system can automatically adjust conditions to prevent spoilage. Similarly, sensors can detect the presence of harmful gases, such as ethylene, which can accelerate the ripening of fruits and vegetables. By maintaining optimal conditions, smart sensors help extend the shelf life of perishable items and reduce food waste.

4. Research and Development

Invest in Research and Development

Investing in research and development (R&D) is crucial for discovering and implementing innovative solutions for food safety. R&D initiatives can explore new technologies, methods, and practices that enhance the safety of food products. By supporting these initiatives, the food industry can stay ahead of emerging risks and continuously improve safety standards.

R&D can lead to the development of novel testing methods that are faster, more accurate, and more cost-effective than traditional methods. For example, researchers are developing biosensors that can detect pathogens in real-time, providing immediate results without the need for laboratory testing. These biosensors can be integrated into production and processing environments, allowing for continuous monitoring and rapid response to contamination events.

Support Initiatives that Explore New Technologies and Methods

Supporting initiatives that focus on exploring new technologies and methods is vital for advancing food safety. These initiatives can lead to the development of novel testing methods, improved processing techniques, and better storage solutions. By embracing innovation, the food industry can ensure that safety protocols evolve in line with technological advancements.

For example, initiatives that focus on improving food traceability can lead to the development of more effective systems for tracking and tracing food products. These systems can provide real-time data on the location and condition of food items, allowing for prompt response to safety issues.

5. Continuous Improvement

Establish a Feedback Loop for Continuous Improvement

Continuous improvement is essential for maintaining high food safety standards. Establishing a feedback loop allows for the ongoing assessment of food safety protocols based on data analytics and insights. This feedback loop ensures that any gaps or weaknesses in the system are identified and addressed promptly.

Regularly Review and Update Food Safety Protocols

Regularly reviewing and updating food safety protocols is necessary to stay ahead of emerging risks. As new threats to food safety arise, it is important to adapt and refine existing protocols to mitigate these risks effectively. Continuous improvement ensures that food safety measures remain robust and relevant in a rapidly changing environment.

Reviewing and updating protocols should be based on a combination of data analytics, industry trends, and regulatory changes. For example, if new research identifies a previously unknown pathogen or a new method for detecting contaminants, food safety protocols should be updated to incorporate these findings. Similarly, changes in regulations or industry standards may require updates to existing protocols to ensure compliance.

Conclusion

Enhancing food safety and public health requires a comprehensive approach that leverages transparency, stringent quality control, technology integration, research and development, and continuous improvement. By implementing and promoting transparent supply chains, embracing innovative technologies, and investing in R&D, the food industry can ensure that food products are safe and of the highest quality. Establishing a feedback loop for continuous improvement further strengthens food safety protocols, ensuring that they evolve to meet new challenges.

This roadmap provides a clear and actionable path for enhancing food safety, ultimately protecting public health and building consumer trust in the food supply chain. As the food industry continues to evolve, these strategies will play a critical role in addressing emerging risks and ensuring that food safety remains a top priority.

Author

Ashutosh Jaiswal

Food Safety Professional

Email: ashuthewall@gmail.com

Website: https://www.foodsafetywithashutosh.com